Effect of the sun on electrical motors

High ambient temperatures, especially during Australia’s hot summer months, can cause electric motors to overheat. Extreme heat impacts the motor’s ability to dissipate heat effectively, which may lead to performance issues or even damage. However, this problem may be addressed through the use of a Mill Motor Sun Shade.

When an electric motor overheats, the first noticeable effects are increased magnetic losses and higher winding resistance. These changes reduce efficiency, generate more losses, and cause additional heating within the motor.

As the motor continues to heat up, it eventually reaches a point where the wire insulation—usually made of an enamel compound—can no longer withstand the temperature. This breakdown of insulation can lead to serious damage.

Some motors are equipped with thermal cutouts to protect against thermal runaway. However, for production equipment, this safeguard is far from ideal as it can disrupt operations.

Possible solutions

To prevent sun-induced overheating, one effective solution is to install a sun shield. These solar shields are placed over the motor/gearbox combination to help control internal temperatures. The main goal is to keep the motor/gearbox within the specified operating temperature range.

When designing a solar shield for mill motors, several factors must be considered:

- Wind loading to AS/NZS 1170.2:2021, Structural Design Actions – Wind Actions (Also refer https://www.standards.org.au/standards-catalogue/standard-details?designation=as-nzs-1170-2-2002

- Installation challenges due to mill foundation and steelwork alignment

- Ease of construction and installation

- Accessibility for maintenance

- Ease of removal

What Dynamic Engineering Offers

Dynamic Engineering offers a complete design solution for mill motor sun shades / solar shades. We can design the solar shades for your specific site conditions, while taking into account the specific mill floor and foundation layouts and relative heights. We can also issue a design report and even go so far as to generate detail fabrication/shop drawings (also refer https://www.dynamicengineering.com.au/industrial/2023/01/30/3d-modeling-and-drafting/.

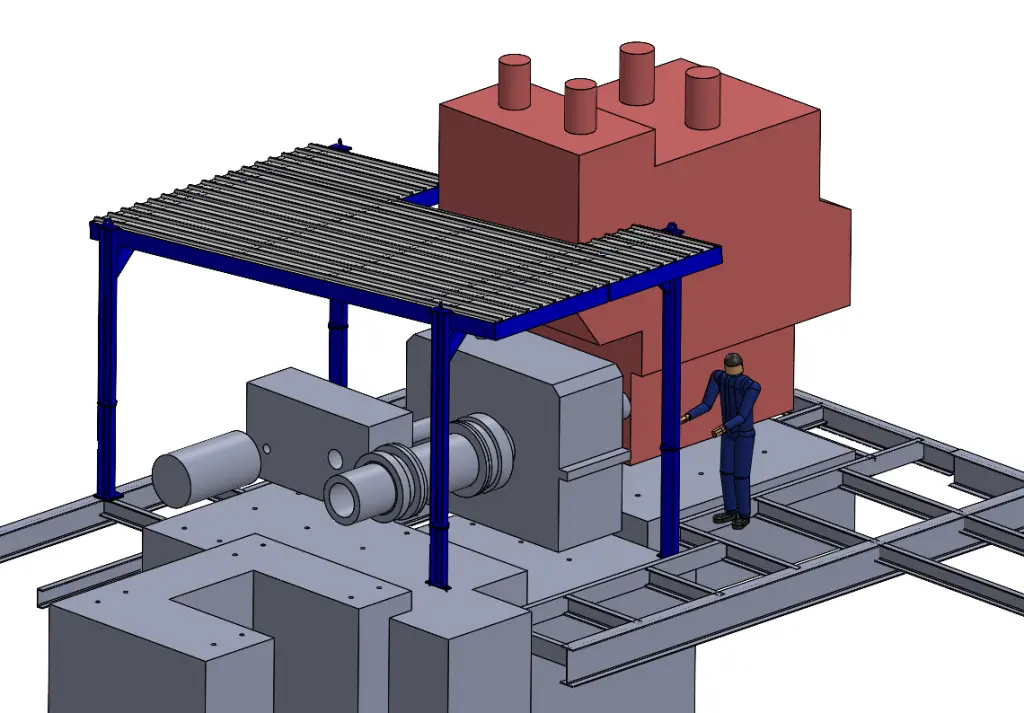

An example of a mill motor solar shield is shown below (with a human included for scale):