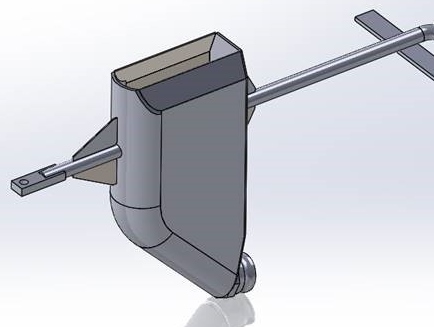

One of our clients had an existing sample scoop which was unable to keep up with the slurry flow. This resulted in spillage and needless added maintenance costs. Below is the existing scoop, showing the spillage clearly:

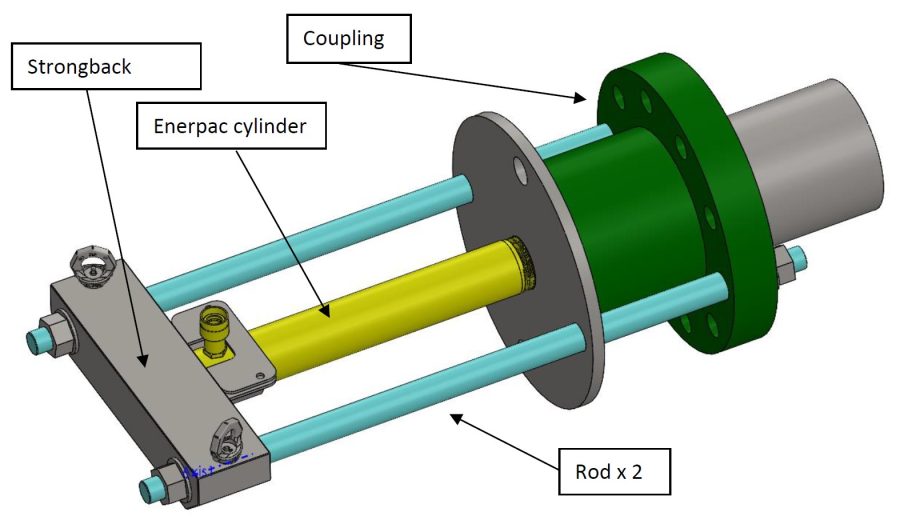

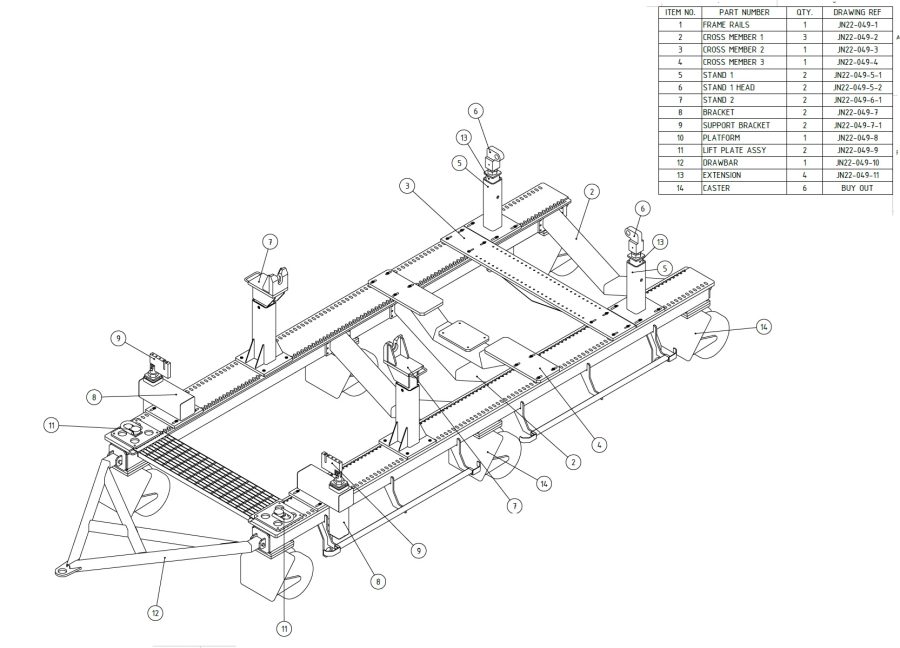

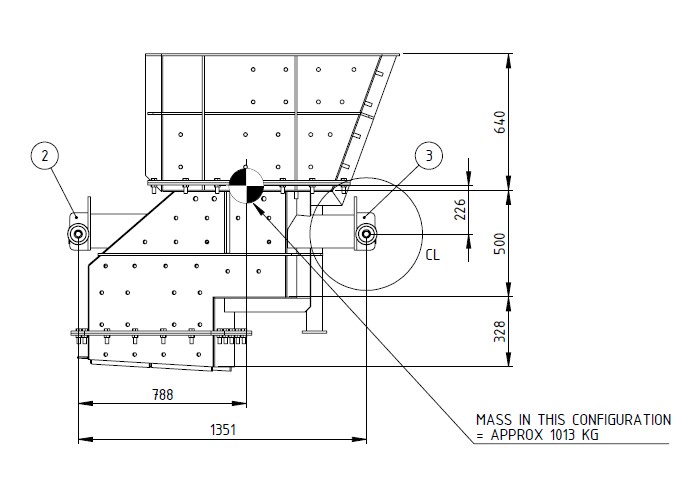

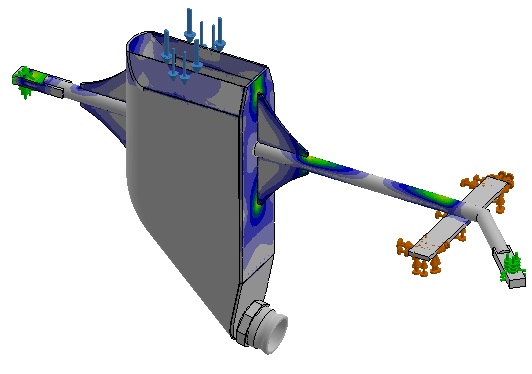

Hence, our client requested Dynamic Engineering to design and supply a larger scoop to handle the flow. Following discussions with the client, we optimaly designed the scoop to withstand this high flow. In addition, we enlarged the scoop to avoid spillage, while still being able to fit in the existing space. This 3D model was analysed with Finite Element Analysis and below is the stress analysis. Lastly, we produced fabrication drawings.

Afterwards the scoop was made and shipped to the client.

In addition, Dynamic Engineering can design manual sample scoops to easily obtain samples. The manual scoop below has a long reach and a scooping mechanism at the handle to gain access in tight spaces.

When analysing any new designs, the Australian Standards AS 3990 are taken into account.

Whether we operate as independent subcontractors or as part of our client’s team, we aim to exceed expectations. In addition, we provide a quality service that will lead to a long term relationship with our clients. We offer proven expertise in engineering analysis and best practice in its application. Contact us to discuss your requirements.