Maintaining an aging plant or structure can be a challenge. This is because the repairs must be perfomed in the shortest time possible whilst still maintaining structural integrity. Furthermore, the maintenance team need to consider the safety of the personnel performing the repairs above all else. With all this in mind, Dynamic Engineering can assist you with your repair procedures. Since we’ve compiled many procedures over the years, you can benefit from our extensive experience.

Typical repair procedures may include:

- design of temporary props

- modifications to an existing structure to make installation easier

- concrete repairs (wear and deterioration)

Our repair procedures include steel structures, concrete structures, monorails and many more. In some cases, like with classified plant, this may require re-registration or registration of alteration to the plant design. This is in accordance with Worksafe requirements (more details can be found here).

Example of a Repair Procedure

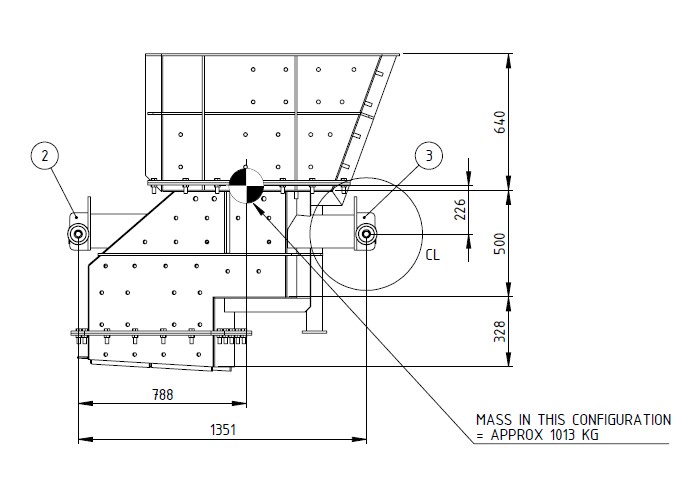

As an illustration, below is a simple example of a repair procedure we designed for one of our mining clients. The item to be repaired is a monorail support column, with the damaged section clearly seen in the next picture:

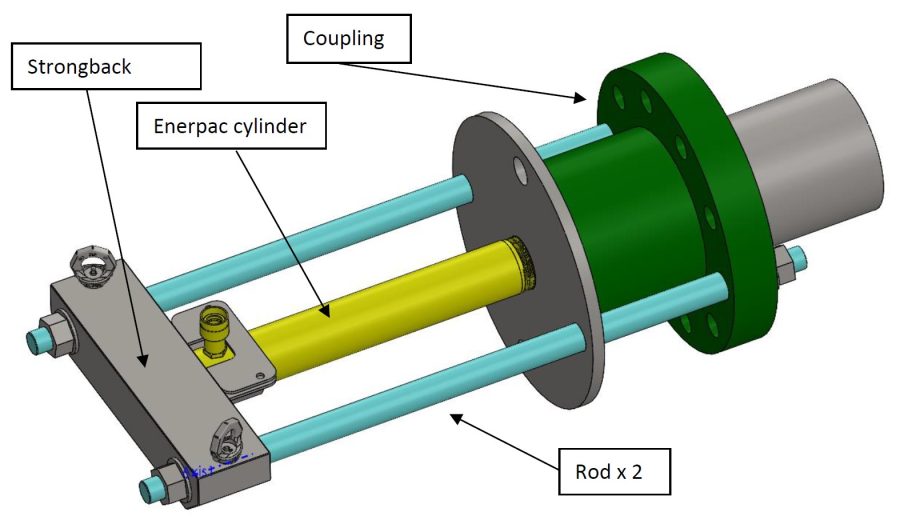

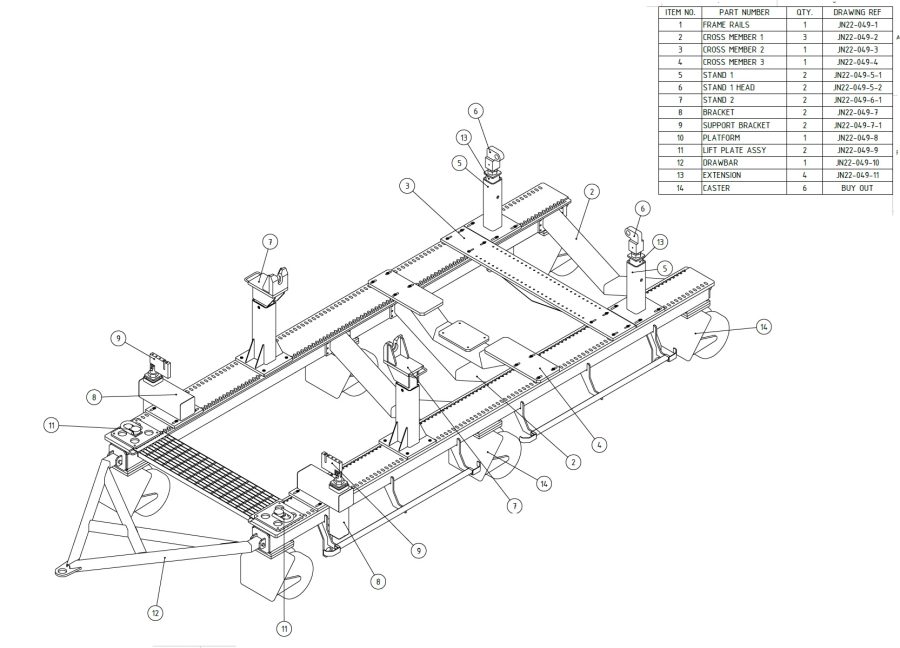

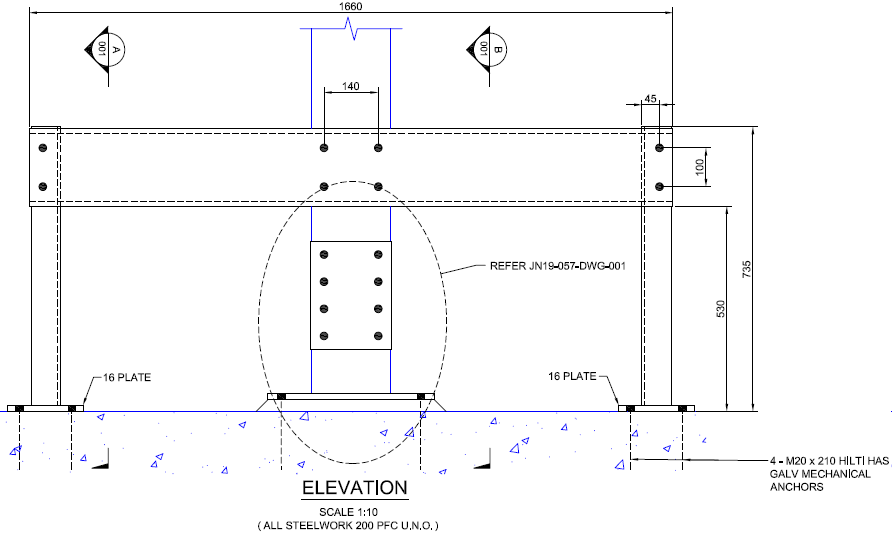

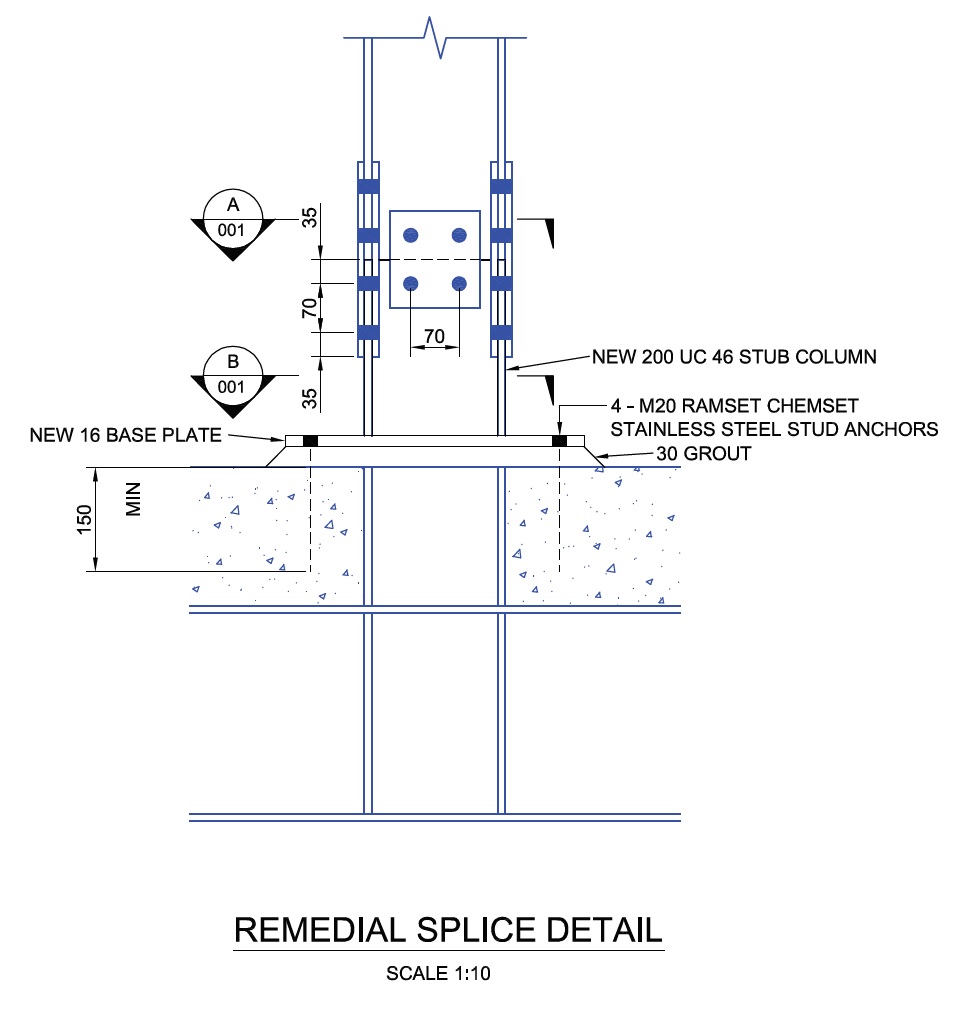

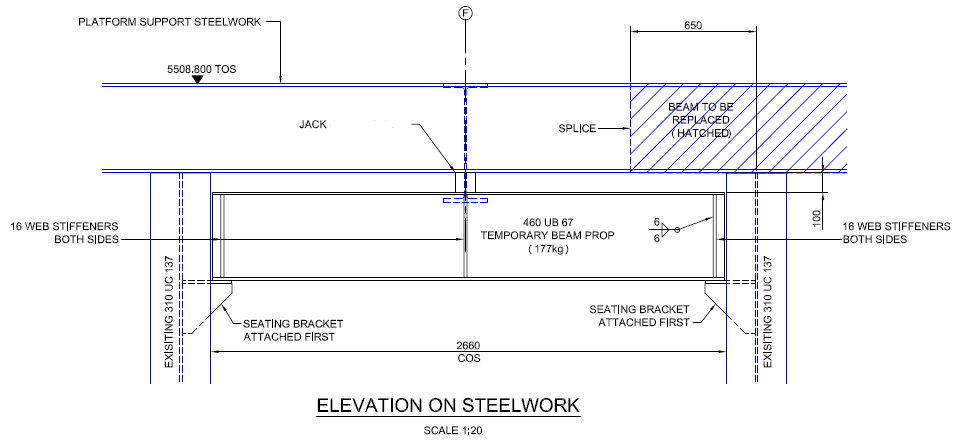

To assist with the repair, we first consulted with our client to familiarise ourself with the problem. Afterwards, we decided to design a bespoke temporary beam to support the platform beams. Then, we provided a detailed repair procedure using the temporary beam prop. Following is an extract of the repair procedure showing drawings to further clarify the procedure.

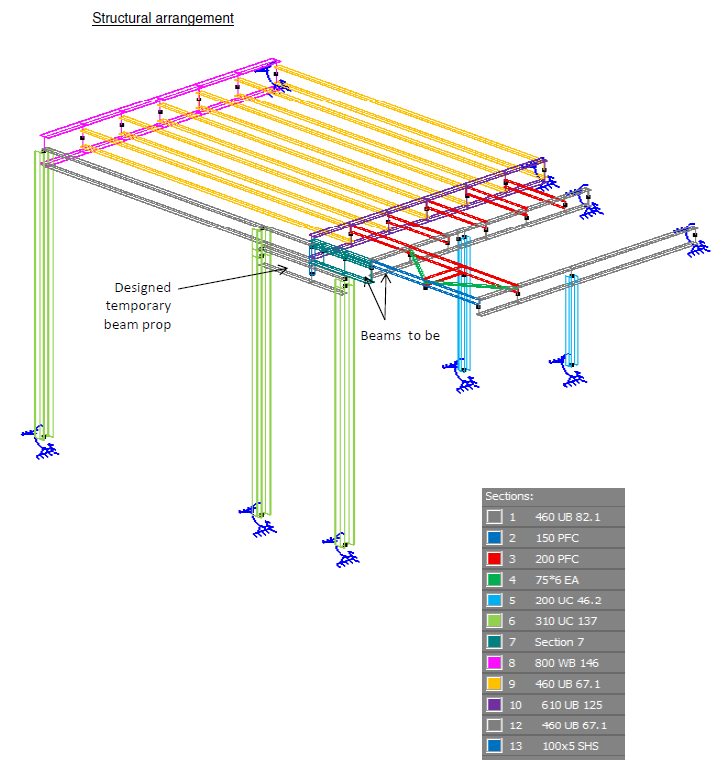

Sometimes, we use Space Gass to design a temporary prop (see below) as this is a very quick and cost-effective way to find a suitable solution. In addition, we do all work in accordance with the relevant Australian Standard, AS 1170.0, AS 1170.1 and AS 4100.

The picture below shows the Space Gass beams:

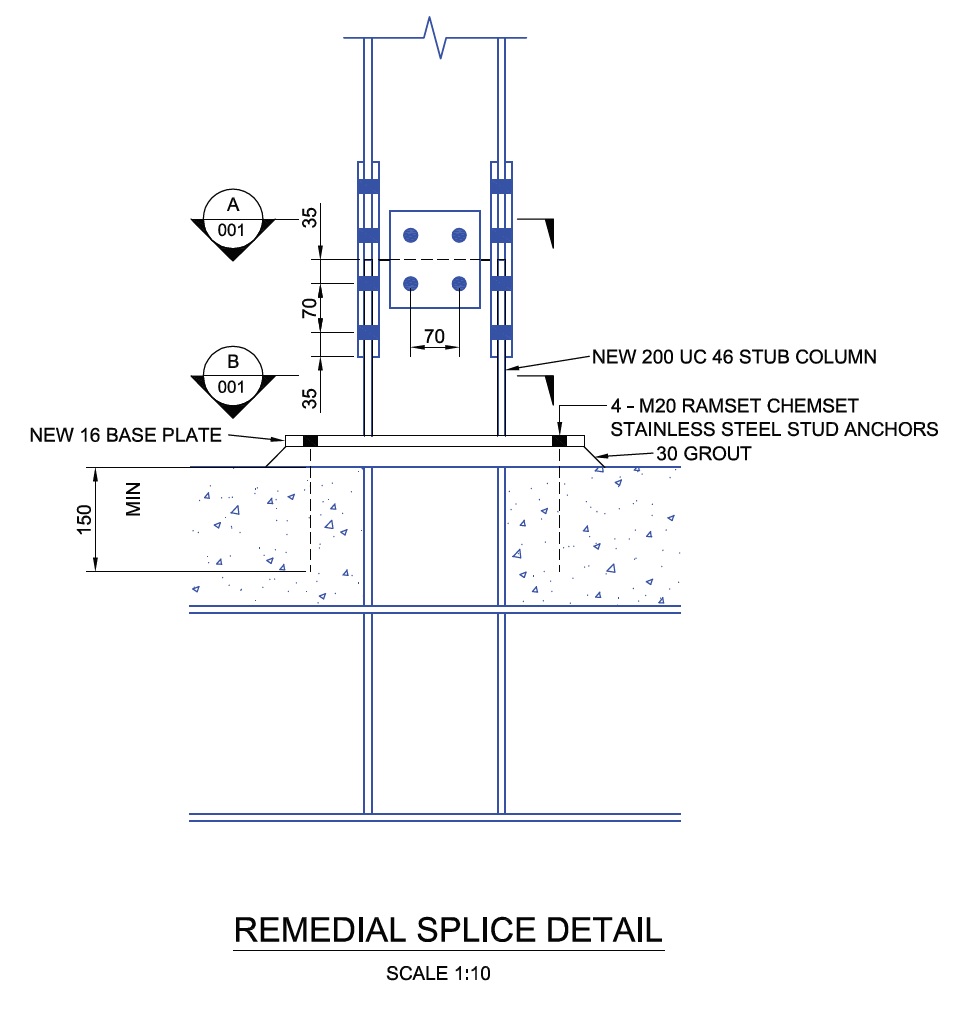

The drawing below shows the steelwork repair procedure:

As can be seen, our clear, well-proven approach can help identify new and innovative ways of providing improvements with minimal down time. After all, your goals are our goals as well. So, to discuss your repair requirements and any other way we can be of assistance, please contact us. We are looking forward hearing from you.