We will listen to your needs and combine it with our many years’ experience. As a result, this will ensure that no compromises would have to be made in the implementation of safety related processes or critical procedures. Additionally, all our work complies with the relevant Australian Standards. As an illustration, following are some of our recent safety equipment designs: a drill cradle, scissor lift, tyre cage and cement kibble.

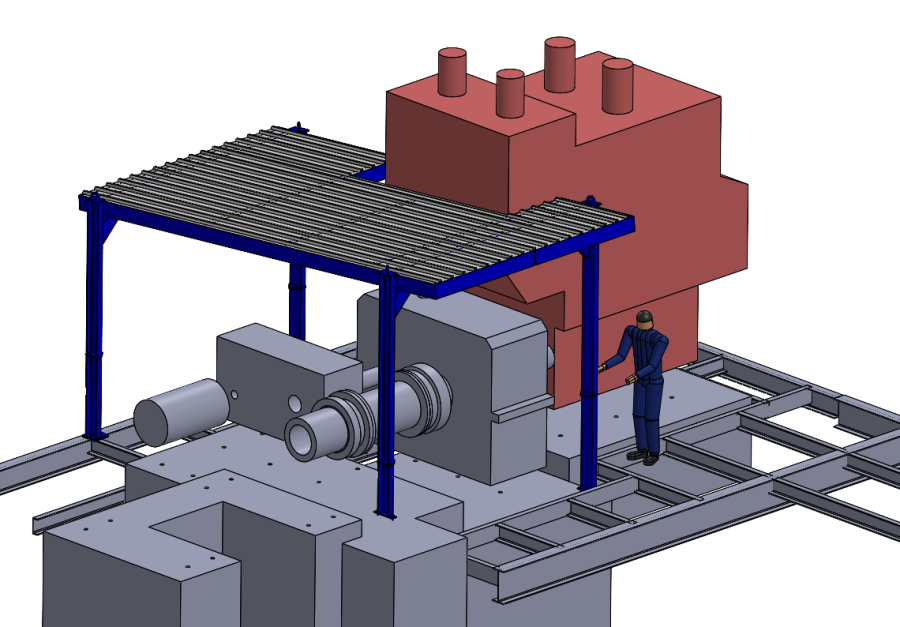

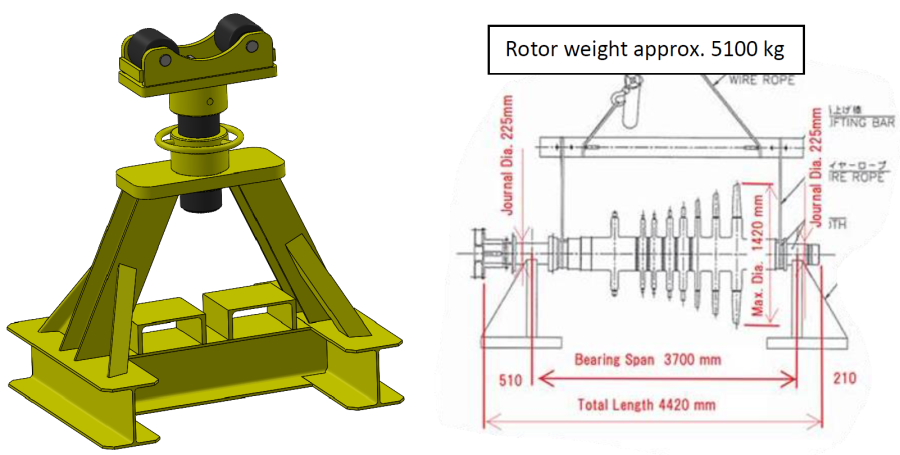

Drill Cradle

A drill cradle is used to retain the drill head in place. Consequently, this will avoid damage and injuries associated with drill head coming loose.

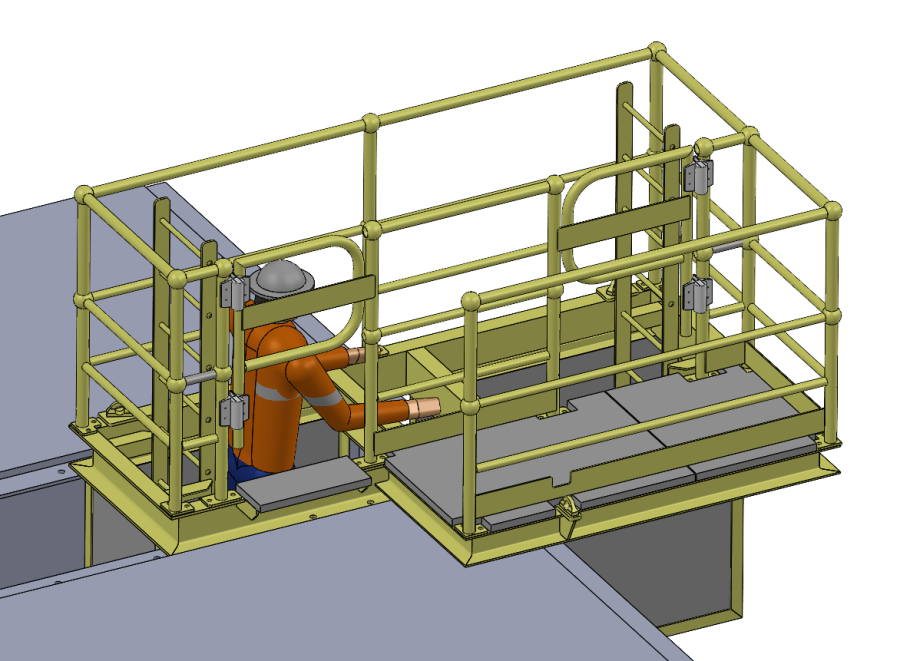

Scissor Lift

Below is a scissor lift we designed to improve access to dump truck rim parts.

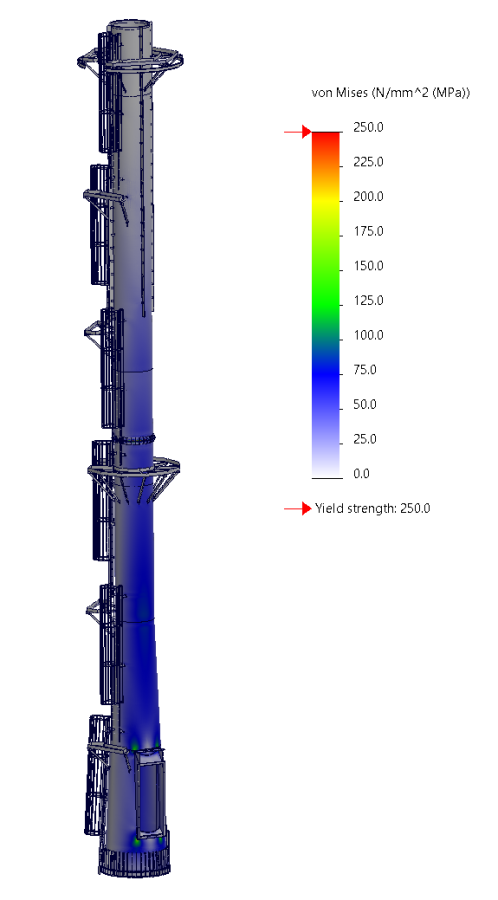

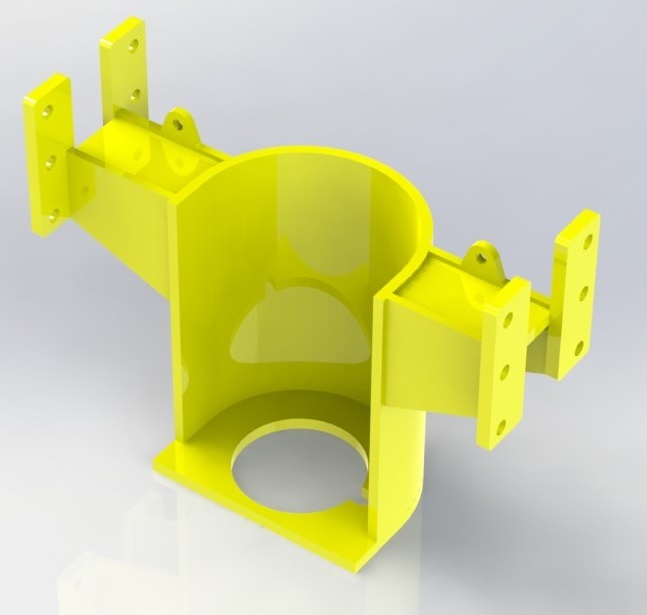

Tyre Cage

We modelled and analysed with non-linear Finite Element Analysis a tyre cage to see if it would be able to withstand a tyre burst event. The picture below shows the CAD model of the tyre cage.

Cement Kibble

Dynamic Engineering modelled and analysed a cement kibble to see if it would safely lift 1T. In addition, the kibble also comes equipped with forklift guides, for ease of transport.

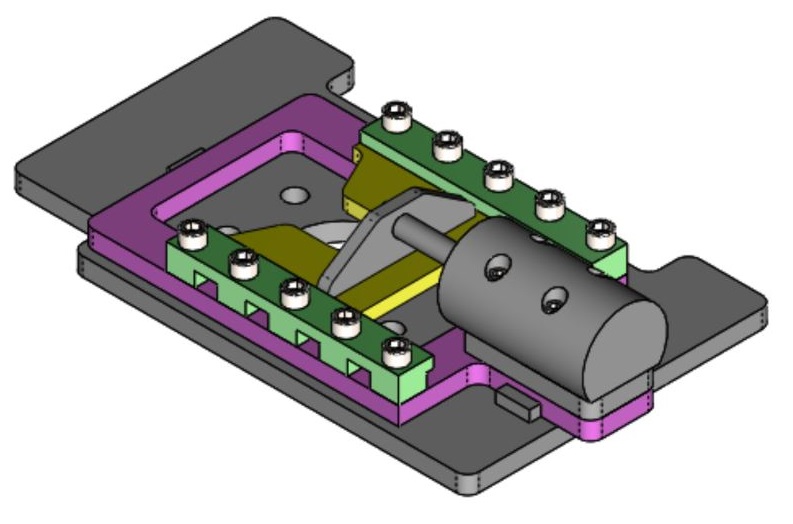

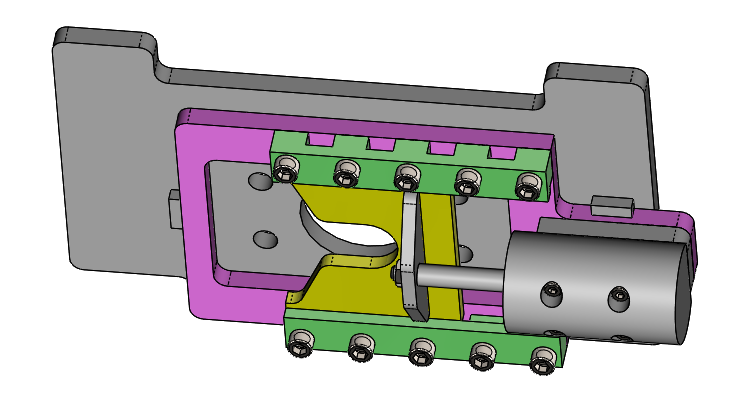

Sliding Plate Assembly

During up-hole drilling, a centraliser (using hydraulic force) holds the rod while the next drill rod is being inserted. If the rod slips it can cause serious damage to the drilling equipment or injury to the operator. To prevent this, a sliding plate drill rod fall protection system could be installed as a fail-safe. For this reason, the sliding plate assembly has to withstand the weight of the rod string including a safety factor. Firstly, we designed one such sliding plate in conjunction with the client. Secondly, to ensure that it was strong enough for the weight of the rod string, we analysed the design. In addition, we checked the assembly against the Australian Standards.

Above are just some examples of how we’ve assisted our clients with projects to improve operator safety. Do you have similar requirements? If so, please contact us to discuss your safety requirements. After all, nothing matters more to us than making sure that you are completely satisfied with the results we deliver.