Sometimes a client has a structure or equipment such as a work stand, which is in use for some time, but for which they have no engineering paperwork. Or alternatively, the nameplate showing the rated capacity has gone missing.

In such cases we can help our client to show compliance with the relevant Australian Standards and mine or safety regulations by applying the following basic process:

- Measuring the existing structure/component by manual measuring or laser scanning. These measurements will also include welding sizes and may include materials testing with a spectrometer.

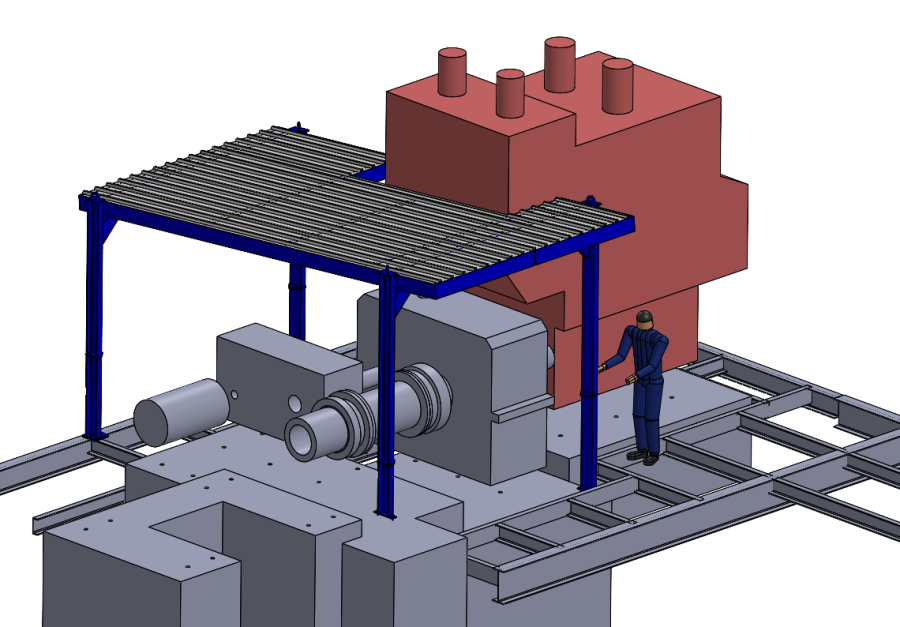

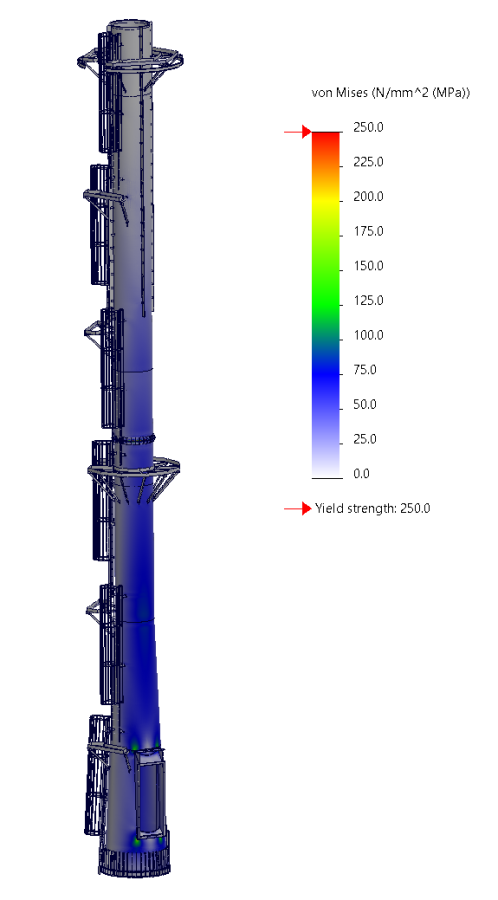

- Modelling the structure/component in a structural analysis program

- Applying loads, load factors and load combinations as dictated by the way the structure / component is used

- Analysing the stresses, strains and deflections of the model in relation to the applied loads and ensuring that this complies with the relevant Australian Standards

- Generating design drawings and a design calculation report

- Generating nameplate drawings

Depending on the application, the physical component may also be subjected to a physical load test to prove the design calculations in practice under safe conditions. This will also reduce the risk associated with unknown welding documentation.

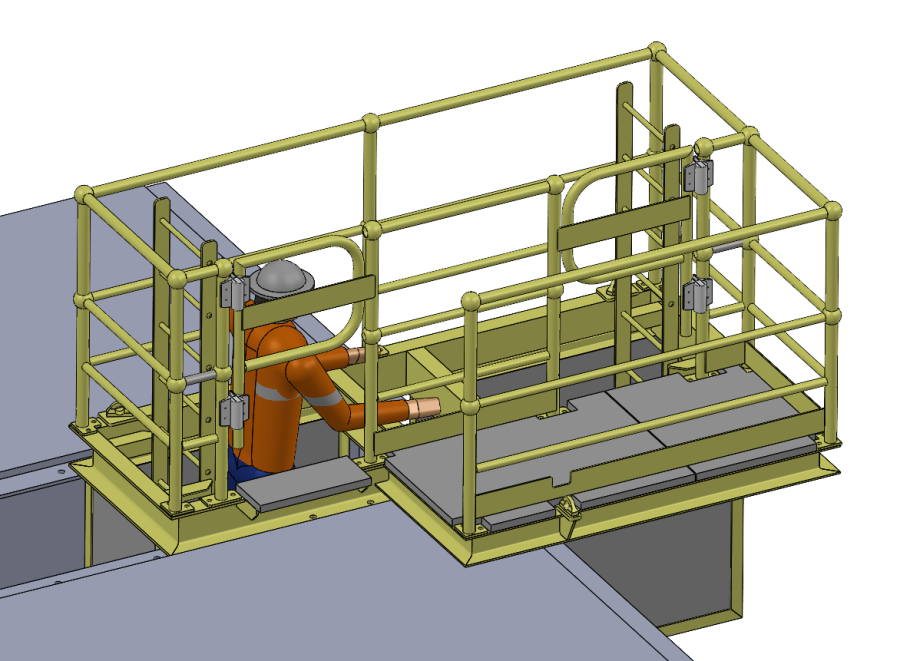

Example of Certification of Stand

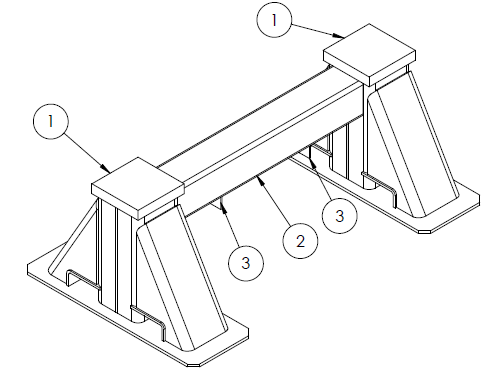

The example below shows an actual stand in use for years:

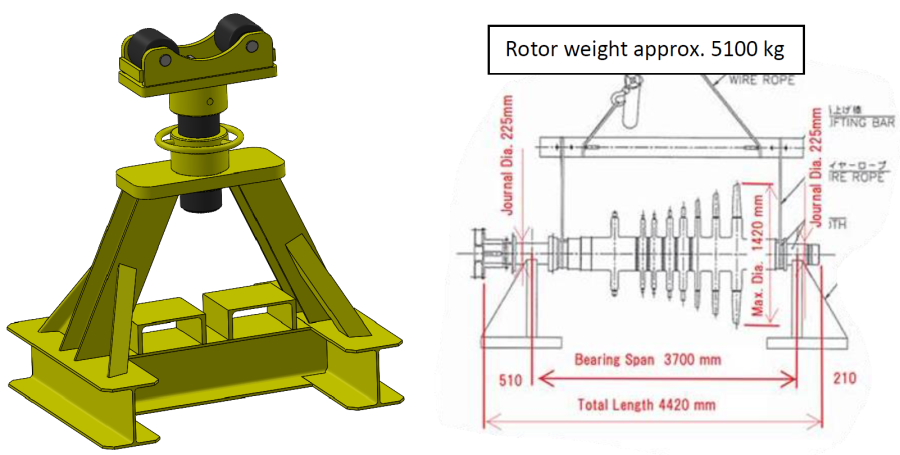

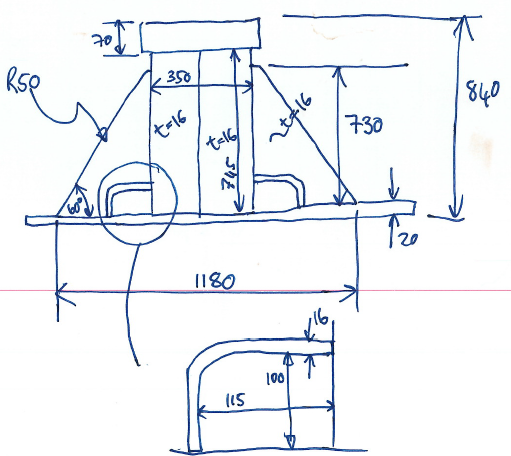

Following is a sketch showing the dimensions measured on site:

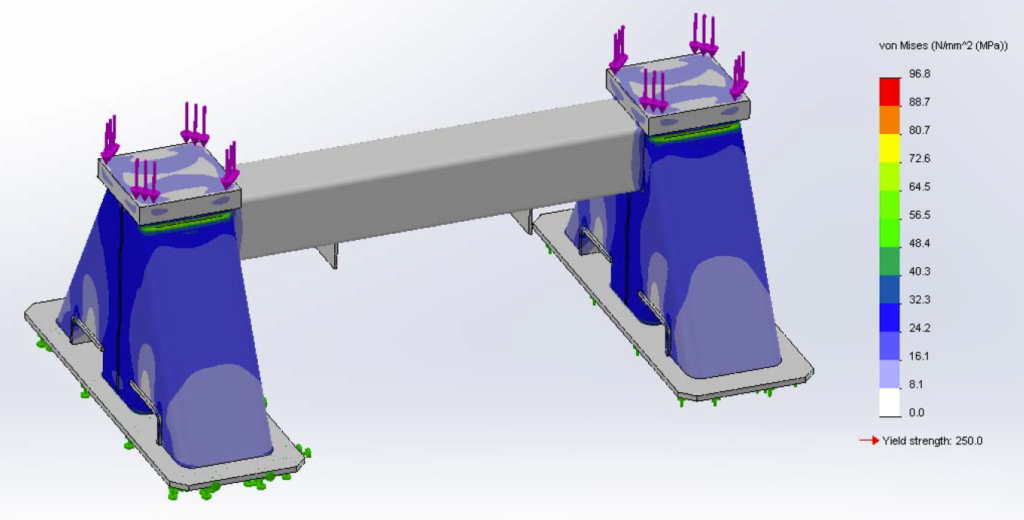

We then use these measurements to create a 3D model and we add loads to find the anticipated stresses and deflections of the stand.

Next, we analyse the 3D model results to determine the rated capacity of the stand.

We have something more to offer our clients as we offer proven expertise in engineering analysis. In addition, our flexible approach means that no assignment is too small. Please contact us if you have any site needs where we could be of assistance.