Dynamic Engineering’s capabilities include specialised lifting equipment design and certification to suit our client’s requirements. By listening to our clients, we transform their ideas into detailed designs. In addition, we design these specialised lifting equipment to Australian Standards AS1418 and AS4991. Following are some examples of previously completed projects:

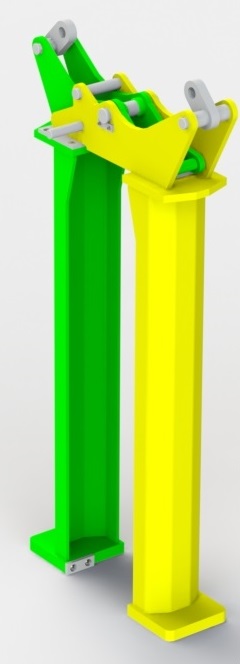

Coil Lifter

The 3D model below shows an example of a 5T capacity coil lifter. This design enables the lifter to “fold inwards” when the coil is engaged, and then by lifting on the outside “ears” the lifter kicks out to enable the lifter to lift the coil vertically. Refer to the second picture to see the lifter in action. After the client approved the design, it was built and tested and is currently in daily use.

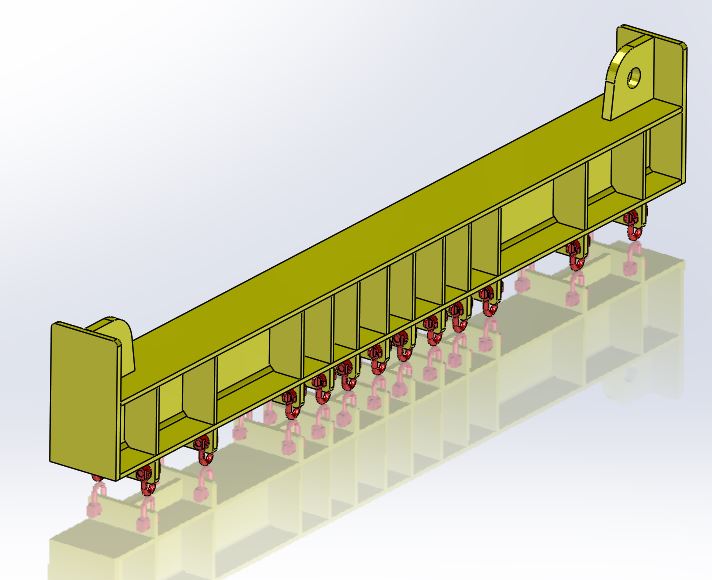

Magnet Spreader

Another example of specialised lifting equipment design is a 12T magnet spreader beam, pictured below. This spreader beam has the capability of lifting 12T with four magnets. For added safety and to improve stability we added four lifting points.

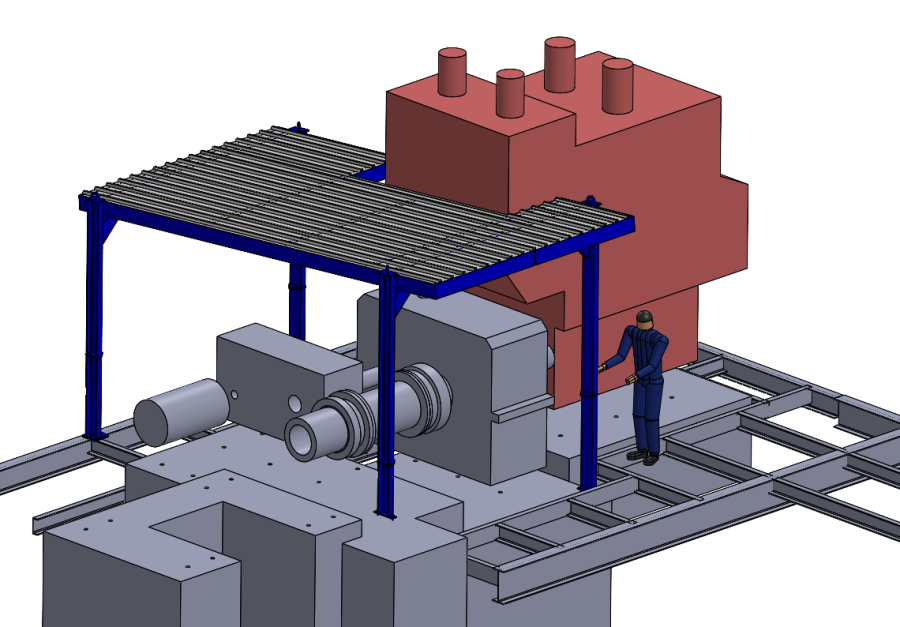

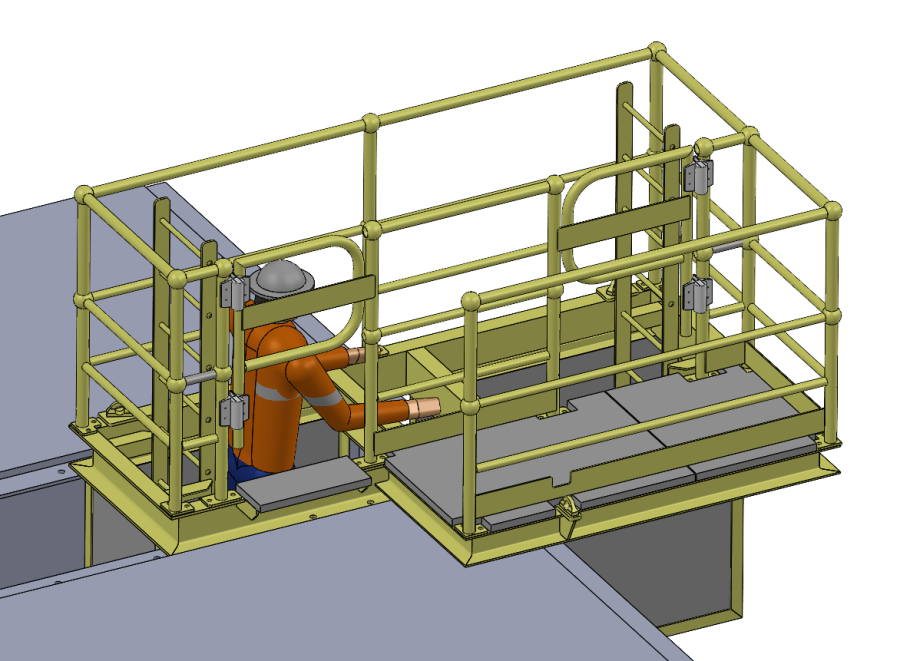

Lifting Beams

When a broken sheave assembly needed to be removed a purpose-built lifting beam was required. Dynamic Engineering worked with our client to find a solution, by firstly creating a 3D design of the proposed design (see below). After completing the design, it was fabricated and then used to remove the broken sheave assembly (following picture).

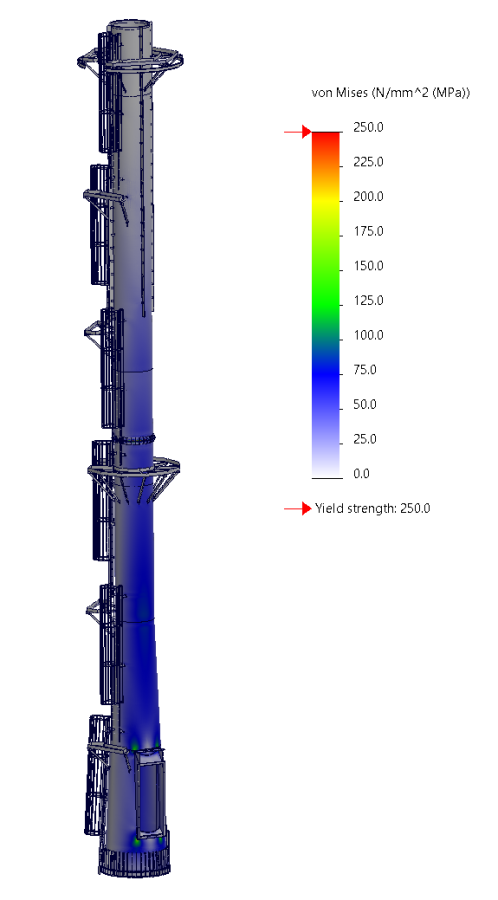

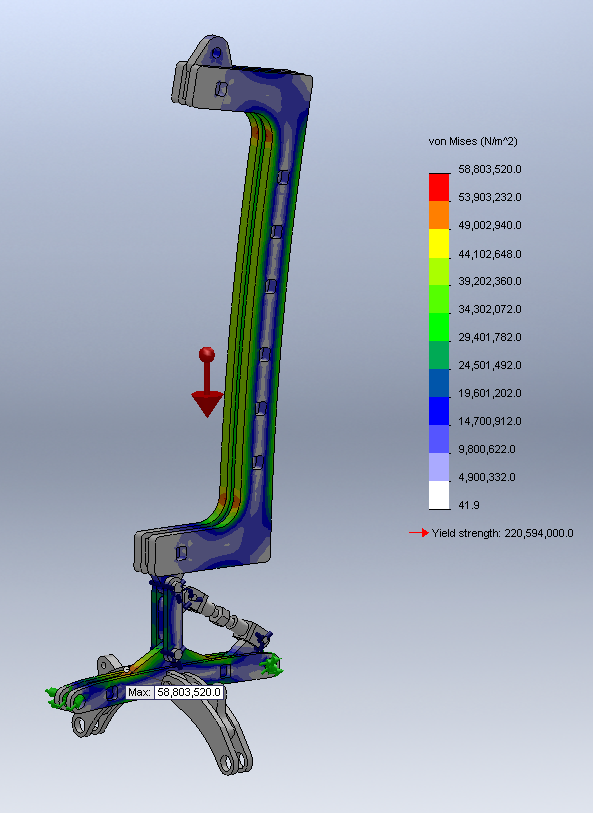

Articulated Alternator Lifter

As part of the design process, we calculated the stresses of the 3D model (see below) of an articulated alternator lifter. As a result, we ensured the design is fit for purpose. In addition, we supplied fabrication drawings to the client and the completed lifter can be seen ready for delivery.

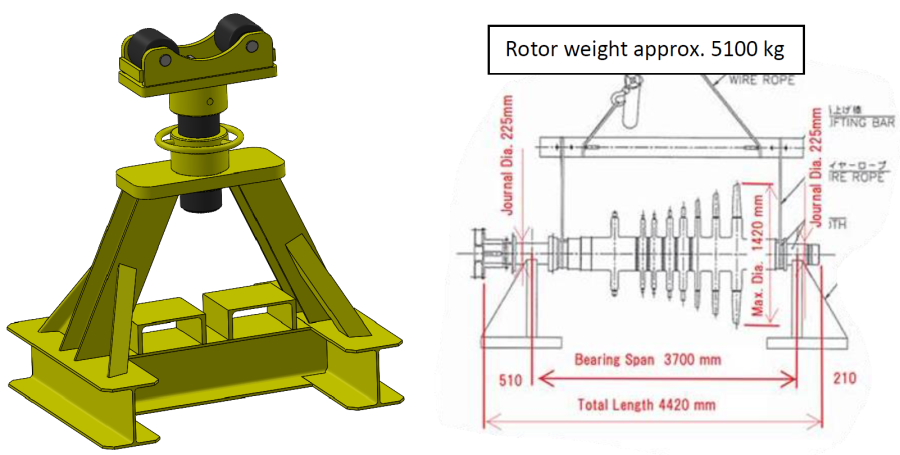

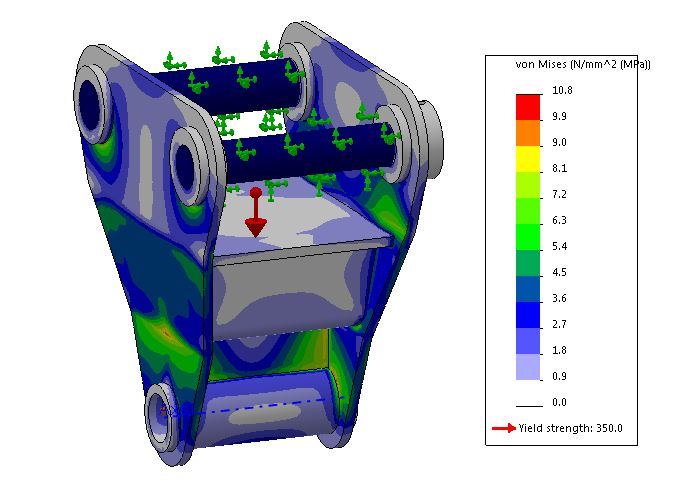

Lifting Adaptors

If you have a specific need, we can assist you as well. In addition to lifting beams, we can also design lifting adapters that are particular to your application. For example, the picture below shows a 7T lifting adapter:

Whether we operate as independent subcontractors or as part of our client’s team, we aim to exceed expectations. Furthermore we provide a quality service that will lead to a long-term relationship with our clients, just contact us to discuss your requirements.