Monorails are extensively used in industry to assist with the movement of equipment. They have the ability to increase production, assist with maintenance and reduce accidents and injuries. As it is a vital piece of infrastructure, it needs to be maintained and inspected often. Dynamic Engineering can assist you with monorail design checks and certifications in relation to AS1418.18. We’ve done many designs over the years. Below are some examples where we assisted our clients:

Monorail Design

In Australia, monorails must be designed to AS1418.18 . The design should take into account the supporting steelwork capacity, the beam bending capacity and also the local bending of the beam flange due to the wheel action. Dynamic Engineering can assist you with performing these calculations. We can create design drawings, perform the calculations and issue a design report and issuing a design certification report. From a design certification point of view we provide a one stop solution

Corrosion inspection

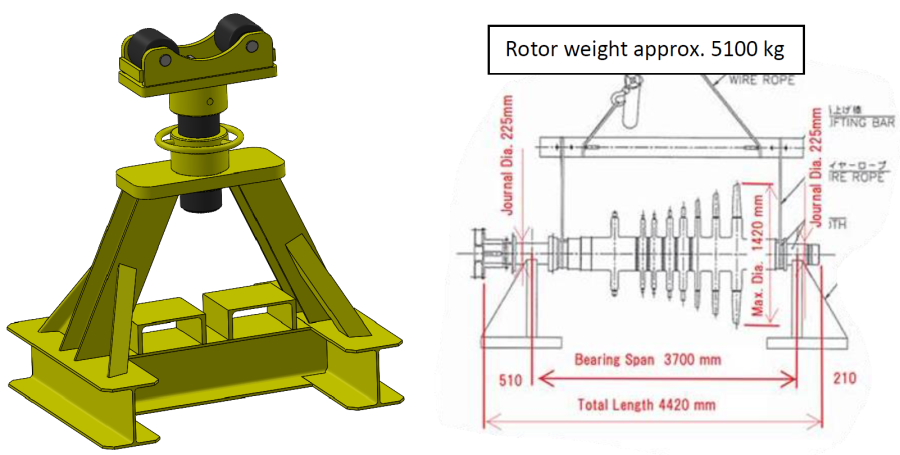

Corrosion is part of everyday life in an underground mine and when equipment has been in use for several years, it can become a safety concern. One of our clients requested us to determine if an existing corroded monorail beam is still fit for purpose and if not, to specify repairs. We did a structural analysis (based on Australian Standards AS1418.18) to find the minimum required thicknesses of the beam to support the hoisted load. The thicknesses were then compared with the actual thickness of the beam to ascertain if the beam was still strong enough. Accordingly, we developed a repair procedure. The photo below shows the corroded beam:

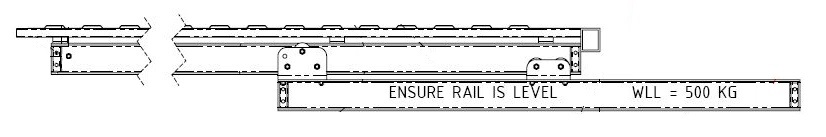

Container monorails

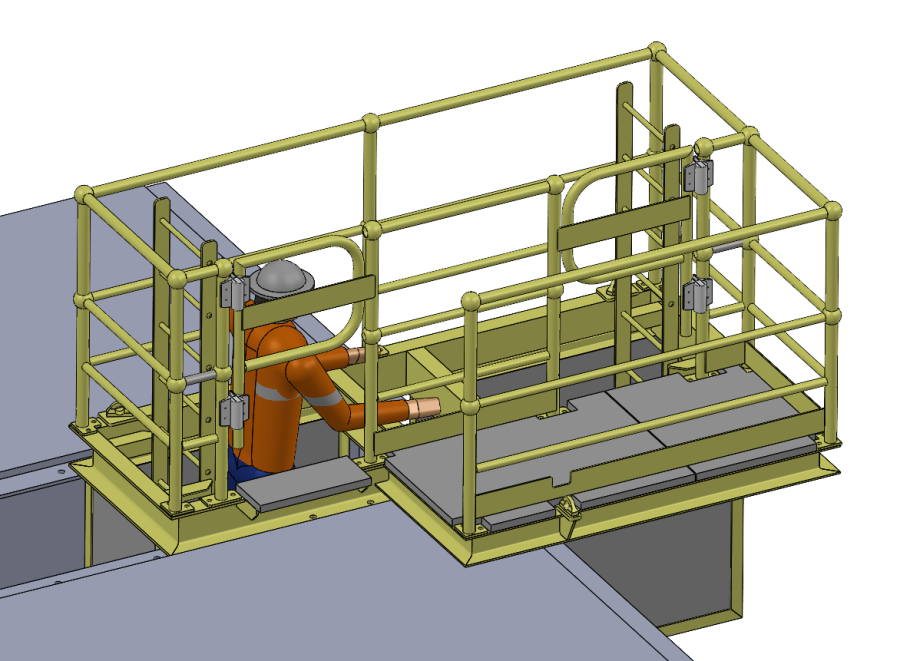

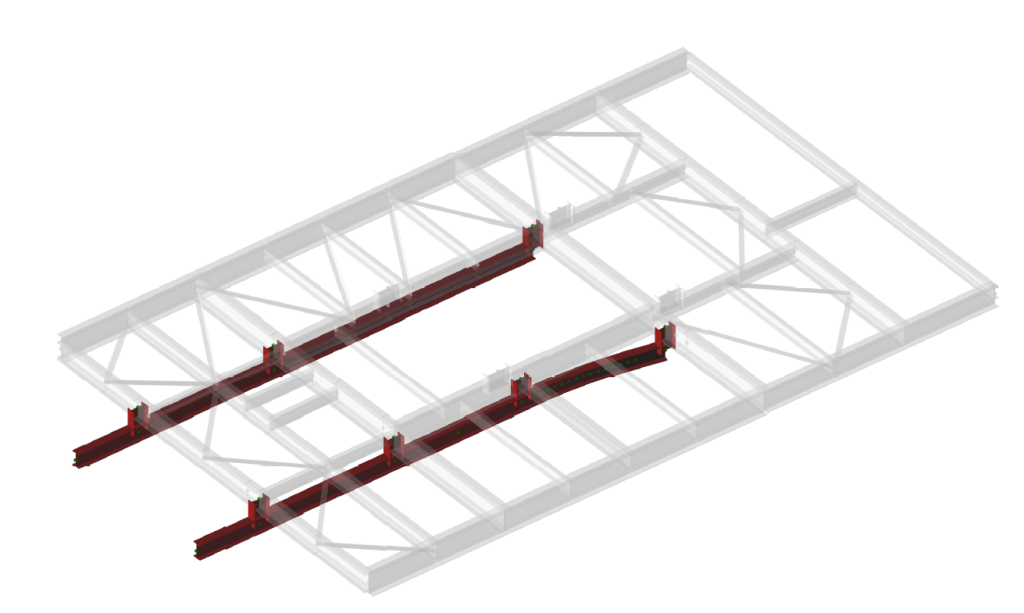

When a shipping container is used to transport heavy items, sometimes monorails are installed inside, that can extend outside the container. These monorails make it easier to lift and move items from inside the container. Our clients asked us to design such a retractable container monorail system according to the relevant Australian Standards (AS1418). In addition, we included the support beams (which connected to the container) in the design, to ensure they were strong enough. In summary, we took the client’s initial concept and turned it into a working model with fabrication drawings. The following picture shows the final design:

Reduction of sway movement

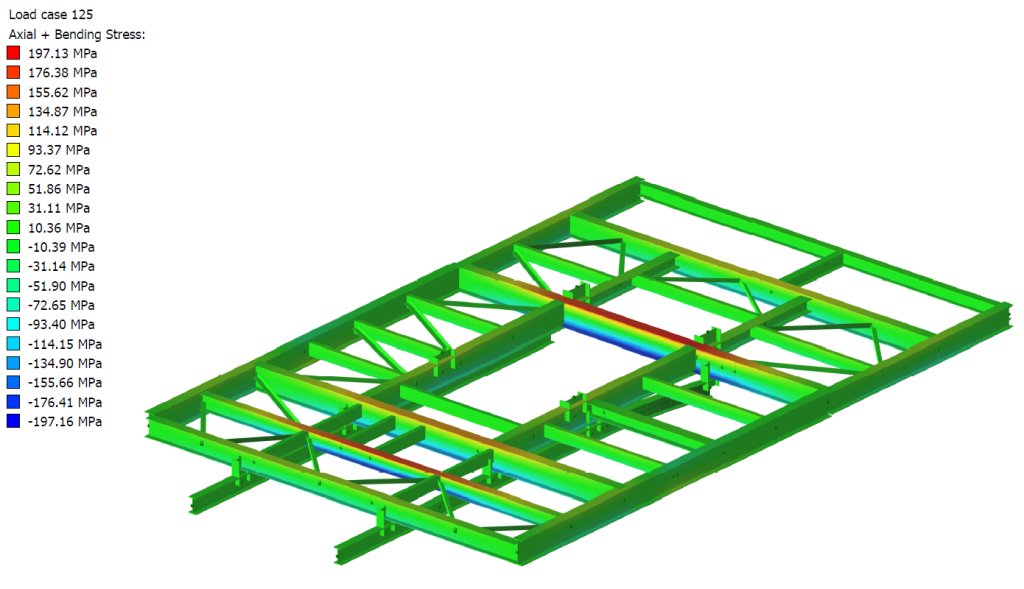

Our client was concerned about the horizontal sway movement of the supporting steelwork of an existing monorail beam. This sway movement occurred mainly when a team member moved a load along the monorail beam. Dynamic Engineering performed monorail design checks on these beams. After analysing the structure, we advised our client that the supporting structure had to be stiffened and upgraded in order to reduce the sway. As a result, our client modified the frame and noticed a significant improvement. The result was another satisfied client.

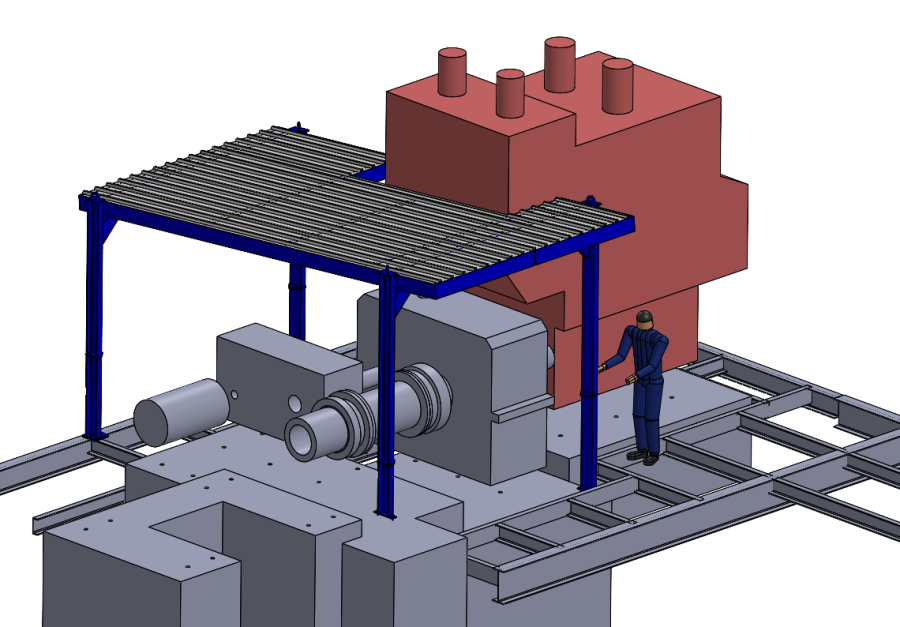

The photo shows the de-coiler frame:

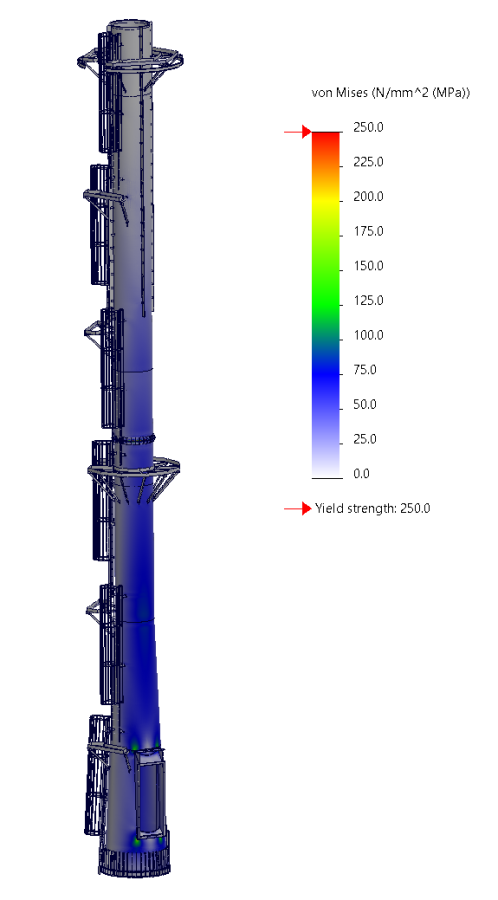

The picture below shows the Space Gass model of the de-coiler frame:

Your goals are our goals too. Our flexible approach also means that no job is too small. We can help to design, develop and install new processes or equipment, improve existing ones and reduce downtime. Please contact us to discuss your requirements.