Background

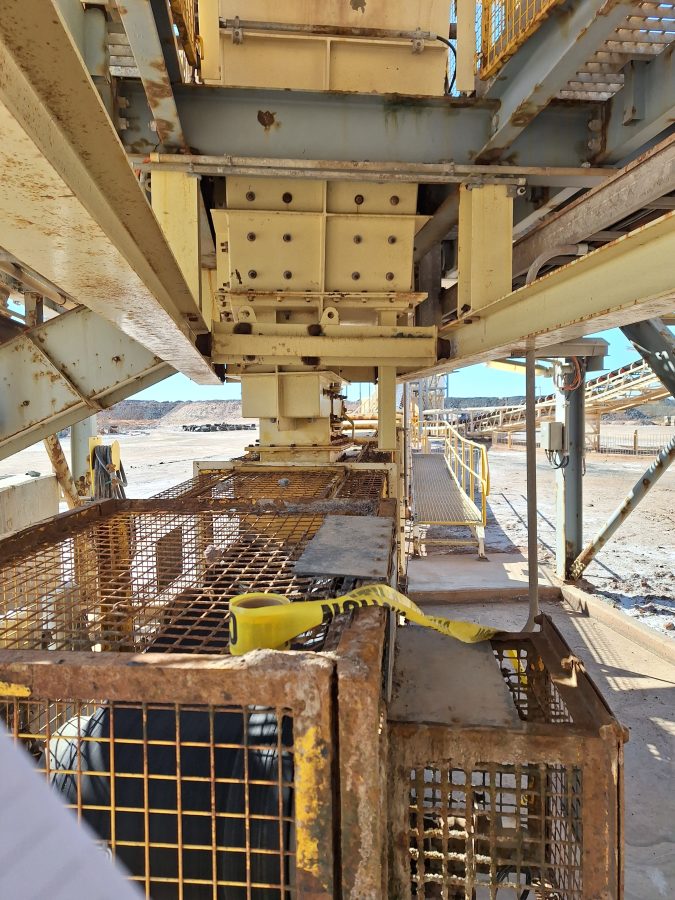

Dynamic Engineering also provide a chute design service. An example of such a chute design project is given below. The goal was to convert an existing conveyor chute for easy removal. Our client was experiencing delays in repairing the chute liner plates (https://bradken.com/products-and-services/mining-and-resources/fixed-wear-systems/wear-solutions), which led them to search for quicker repair methods. One innovative solution was to turn the existing chute into a removable one for quick replacement. Dynamic Engineering eagerly took on this challenge to develop the chute system. This highlighted our commitment to finding effective solutions for our clients despite it being unconventional.

The removable chute solution

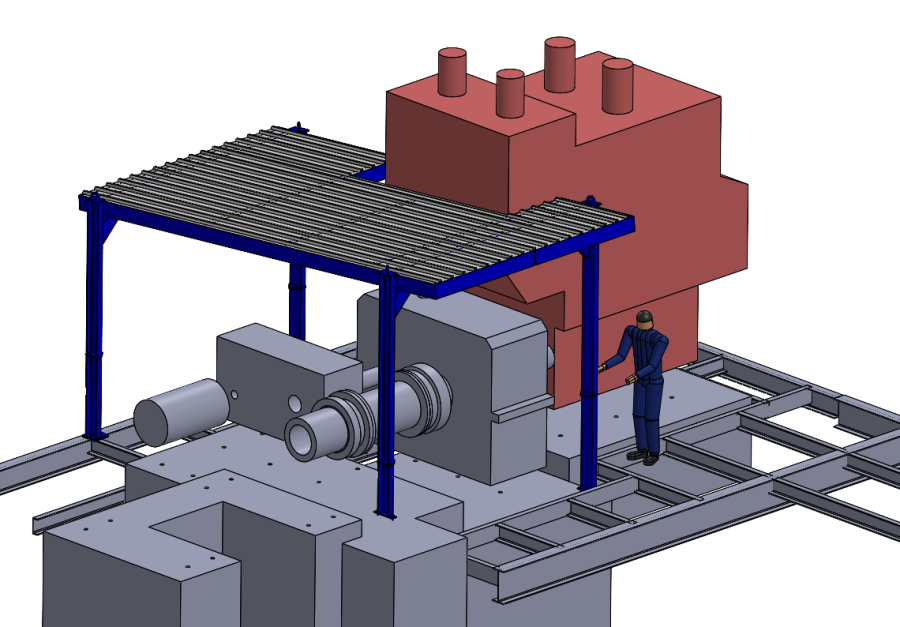

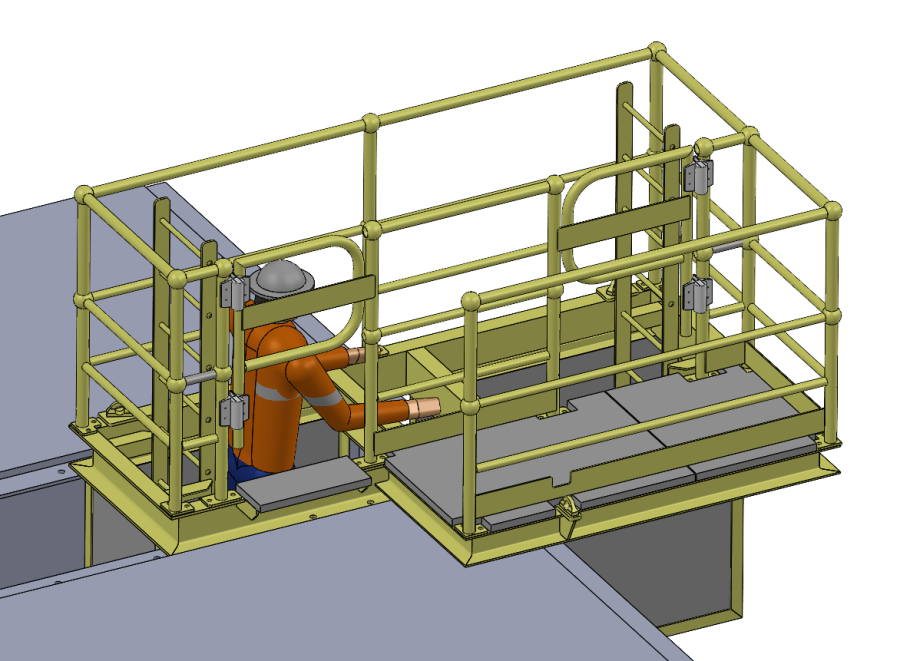

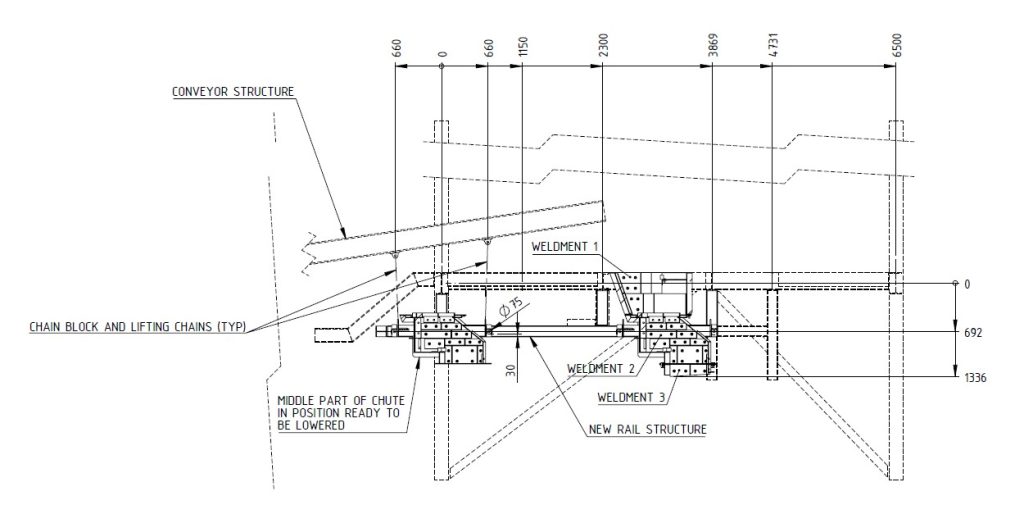

We added more flanges to the chute for high wear areas. We also put wheels on it for easier positioning. To remove it, we lower it onto the rails, pull it out, and then use a lifting system from https://www.dynamicengineering.com.au/industrial/2020/09/27/specialised-lifting-equipment/ to bring it to the ground. We use a crane to bring in a standby chute, connect it to the lifting system, and then reverse the process. This way, we can do repairs in the workshop after the shutdown. Plus, the welder doesn’t have to work inside the chute, which makes the repair process safer.

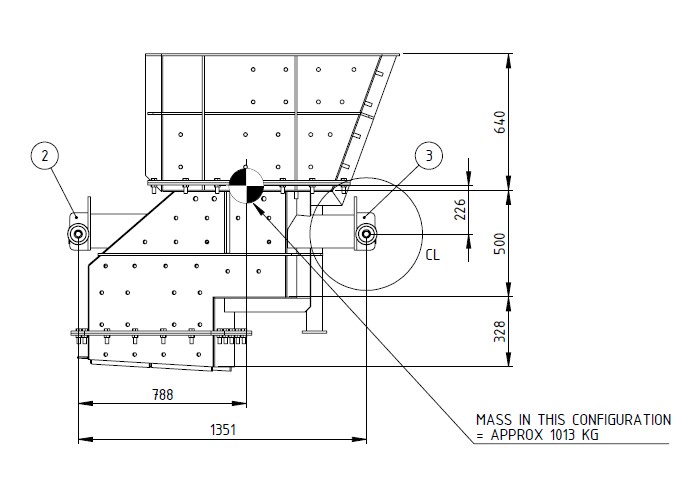

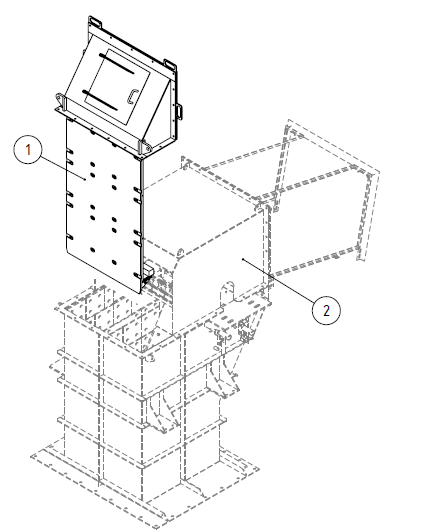

Here’s a view of the removable chute, showing the wheels and the positioning of the flange above them. Additionally, you can see a leg at the back, which aids in stabilizing the chute when it’s lowered to the ground.

Revised chute liner layouts or materials

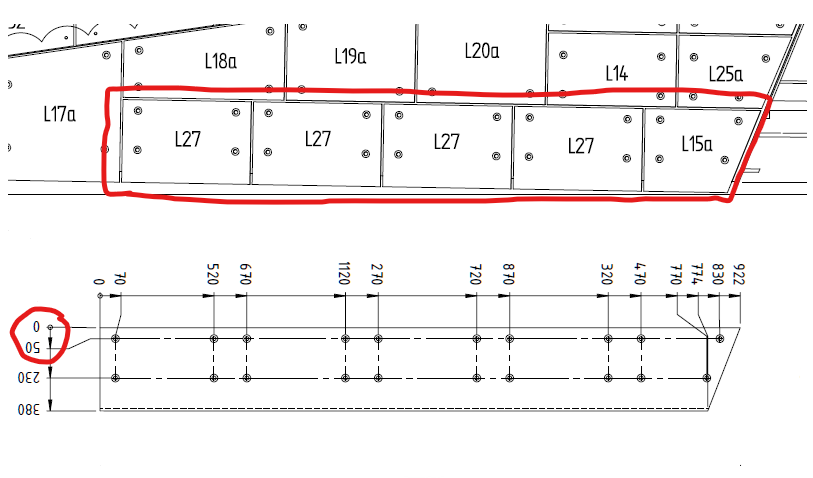

Dynamic Engineering can also assist with any changes to existing chute liner layouts. For example, smaller liners can be grouped together to create larger liners that take less time to replace. Below is an example where smaller liners were grouped together to make larger liners in a bit to reduce the time it takes to replace them.

Drop In Chute Liner

Dynamic Engineering recently designed a lift-out liner plate solution for conveyor headchutes. For elevated chutes, workers can remove liners from the top without using scaffolding. This method also reduces downtime by allowing them to replace multiple liner plates at once.”

Do you have a similar application? Do you also want to take advantage of the reduced downtime or higher safety associated with a removable or drop in liner chute system or a revised liner layout has to offer? Hit the “contact us” tab now and give us a call so that we can discuss your requirements