Maintenance and cleaning of mine site vehicles are always ongoing on a mine site. For this reason, we designed a wash bay vehicle ramp to our client’s following requirements:

- Constructed from large, welded assemblies that can be transported easily and that would minimise construction time on site – modular.

- Galvanised surface treatment.

- Open sections to make it easy to monitor corrosion and damage.

- Capable of handling certain site vehicles.

- Fully compliant with the relevant Australian Standards.

- 5T capacity.

- Incorporated vehicle wheel guides (safety).

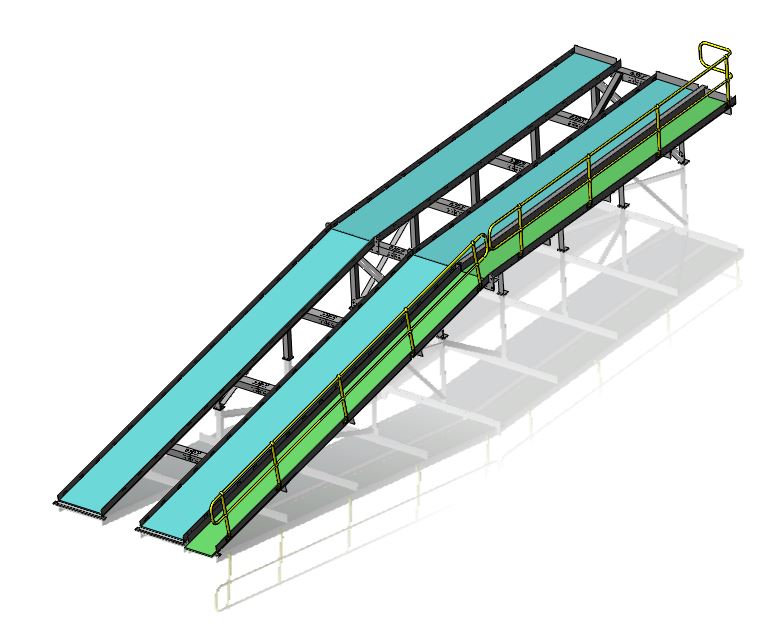

Below is the final 3D design for this ramp. It complies with all of the above requirements and is currently installed at a few mine sites around WA. For ease of transportation, it was constructed in four large sections, which was later bolted together on site with splice plates. In addition, mine personnel attached the ramp to the concrete with mechanical anchors. The all-important feedback from our clients was very positive, because the ramp was easy to transport, install and use. Furthermore, the construction was of a high quality resulting in years of service. This is an example of a simple design that just works well. Since we used CAD to design the ramp, we had a very cost-effective way to visualise the final design and to make changes very easily.

Below workers are installing the fabricated ramp on site:

Contact us to discuss your specific wash bay vehicle ramp requirements.