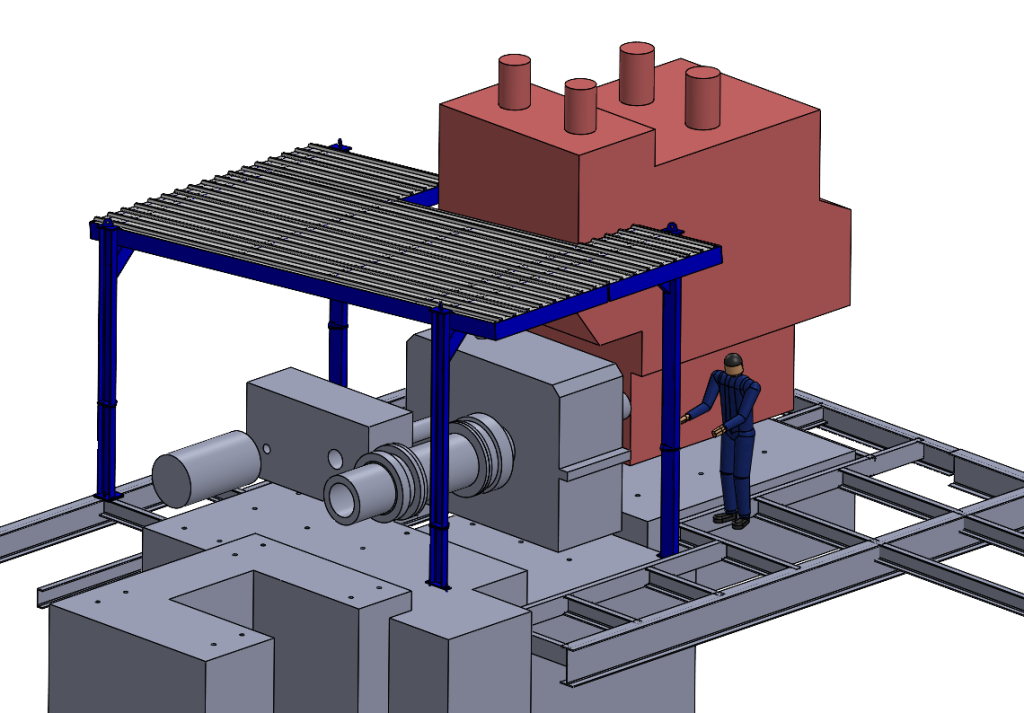

Mill Motor Sun Shade

Effect of the sun on electrical motors High ambient temperatures, especially during Australia’s hot summer months, can cause electric motors to overheat. Extreme heat impacts the motor’s ability to dissipate heat effectively, which may lead to performance issues or even damage. However, this problem may be addressed through the use of a Mill Motor Sun …