New Front Underrun Protection Devices improve safety and increase protection, but could also be very costly or pose a safety risk if not designed properly. At Dynamic Engineering, we reduce this risk by means of Finite Element Analysis before physical testing is performed. We can determine the expected deflection of the FUPDs to ensure it is within acceptable limits before you perform costly destructive testing.

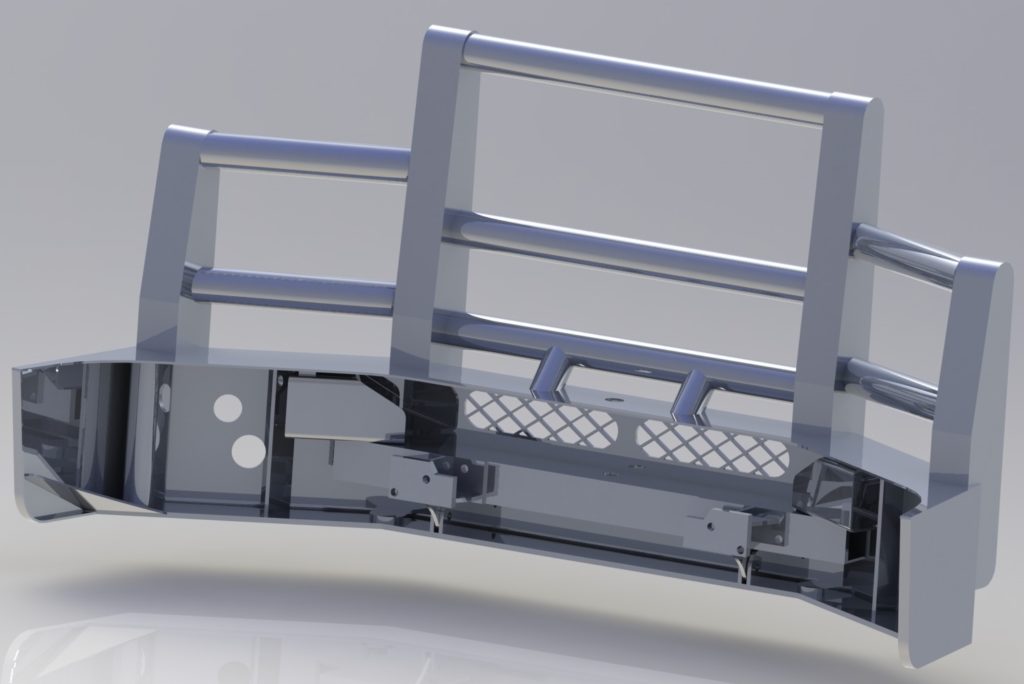

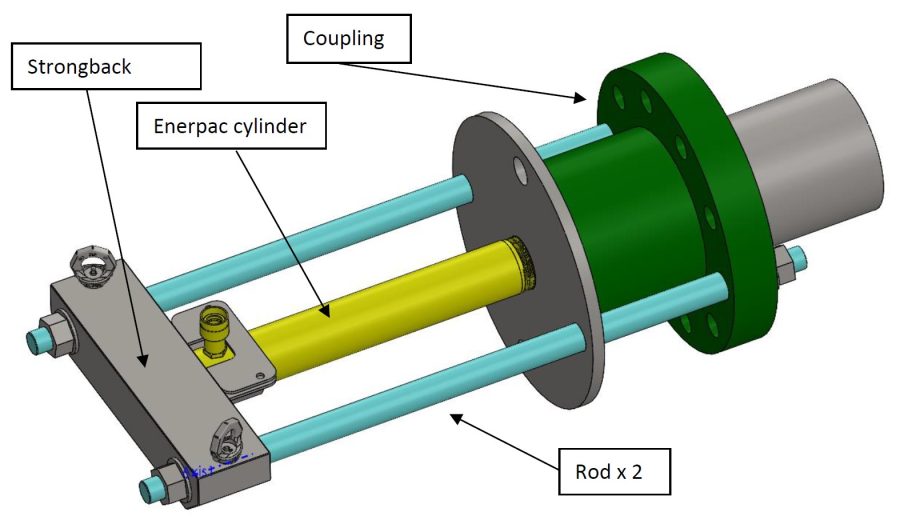

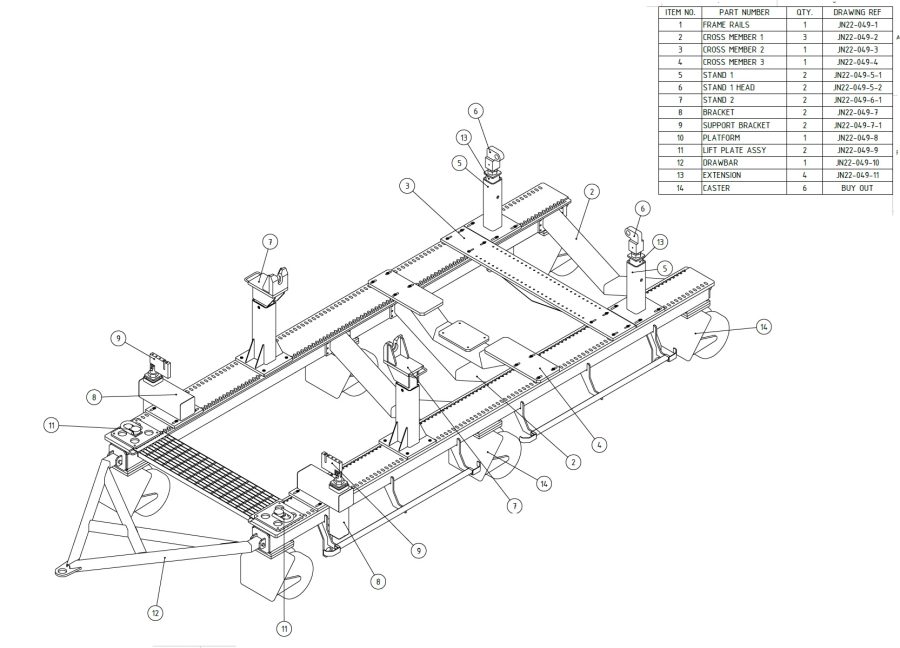

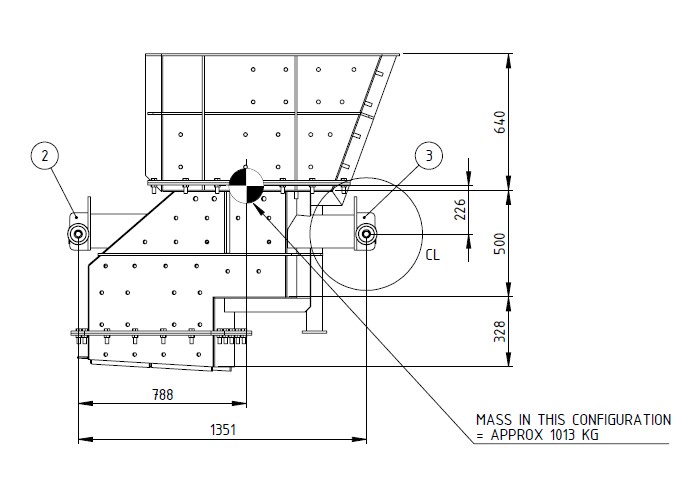

First, we construct a 3D model of the equipment and place loads and constraints on the model to simulate real life use. With Finite Element Analysis, we analyse the resultant stresses and deflections to ensure a safe working design. Afterwards a full physical test in completed in accordance with United Nations ECE Reg 93, conveniently at our client’s premises. Afterwards we provide a full report based on the tests. Furthermore, we can also produce full fabrication drawings and laser cut files.

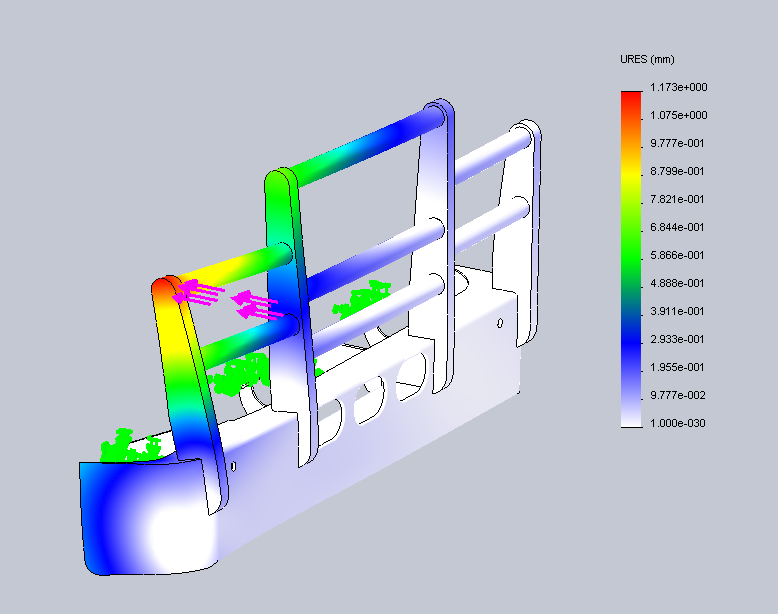

For example, the picture below shows the deflection of the bullbar:

Deflection plot for load at high position

We have recently completed deflection testing on several Front Underrun Protection Devices (bullbars) for K Craft. The photo below shows a test in progress. This usually takes place at the client’s premises.

Testing

We strive to provide cost effective engineering support in very quick turn-around times. This makes us the ideal partner for small to medium sized clients that need more flexibility from engineering contractors. Contact us to discuss your Front Underrun Protection Devices requirements.