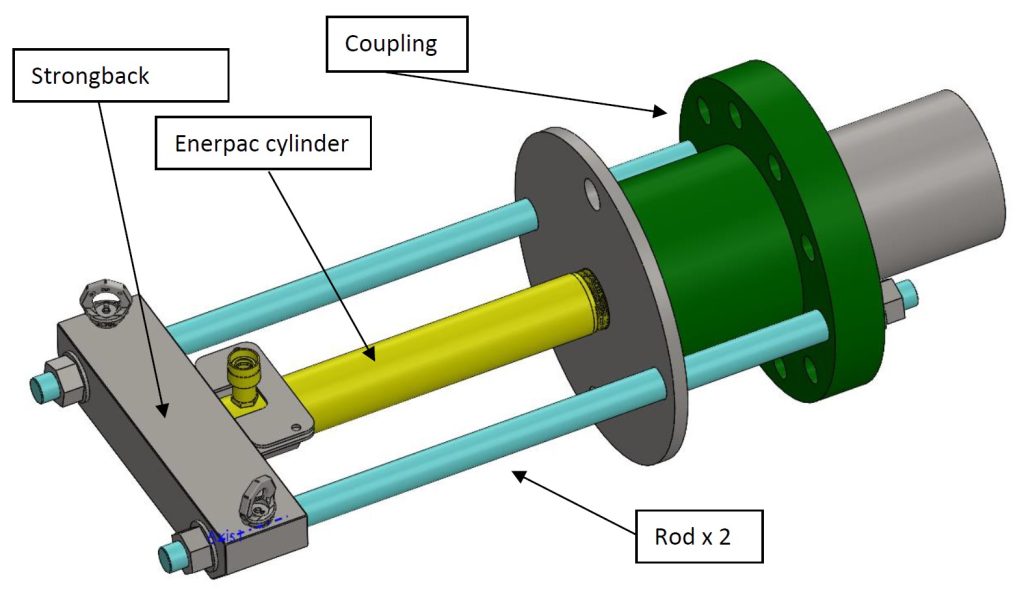

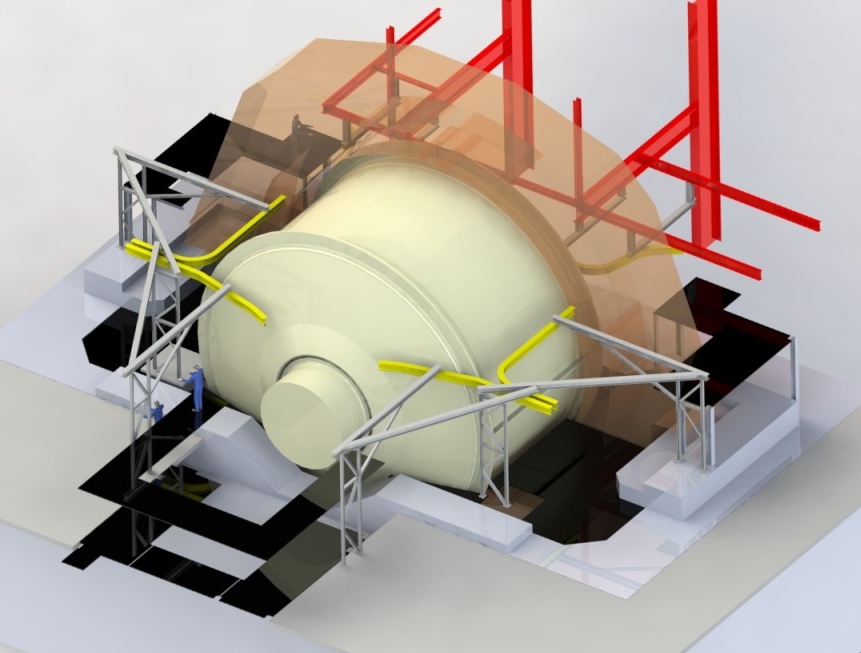

Strongback puller design

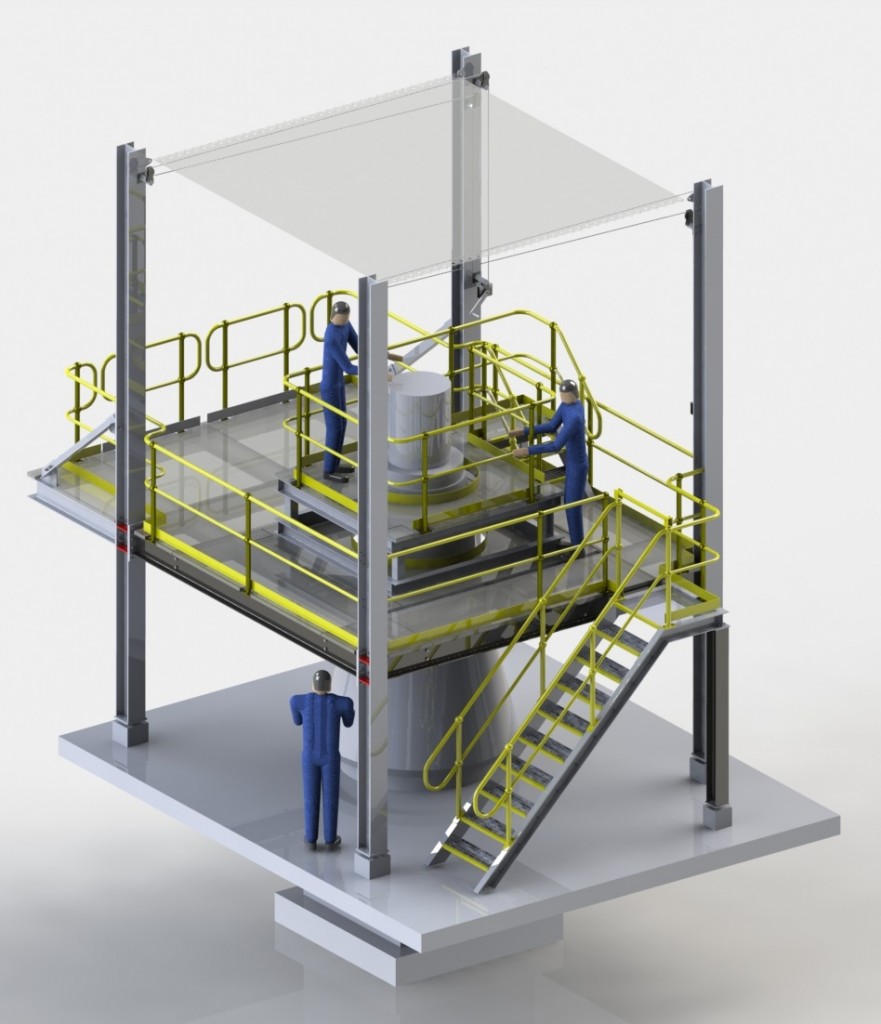

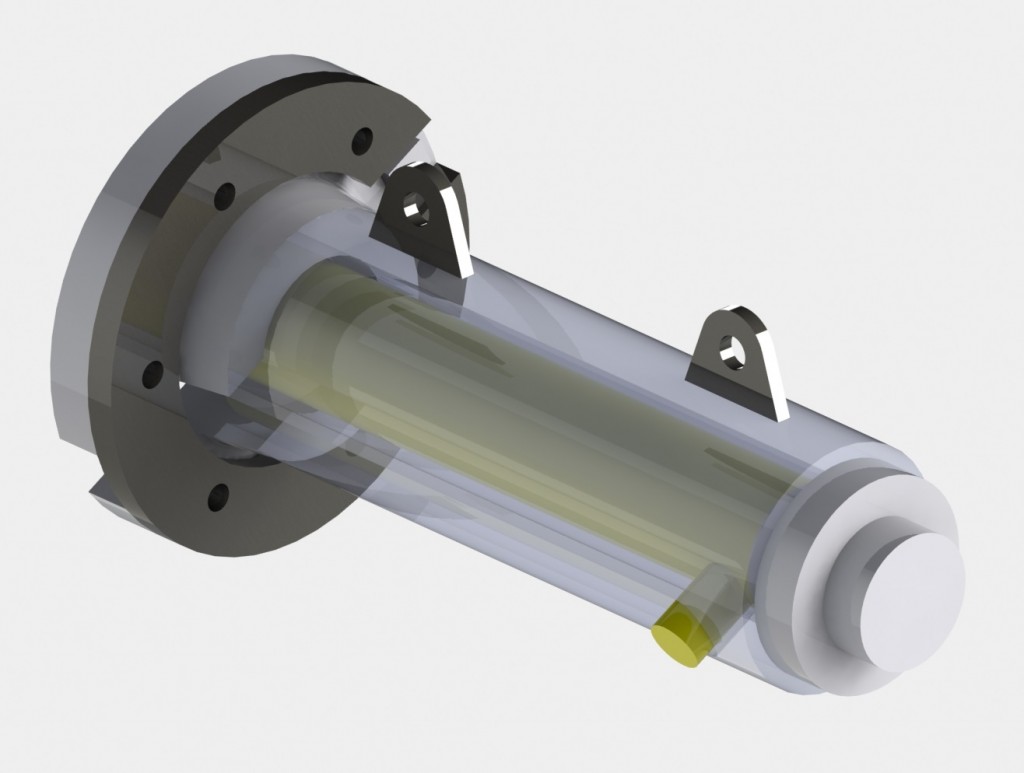

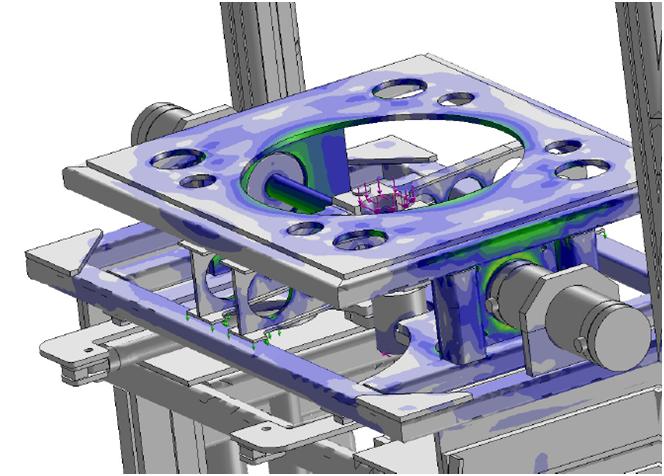

Strongback pullers, alternatively referred to as hydraulic pullers, serve a vital function in efficiently removing shaft-fitted components like bearings or couplings. By harnessing controlled hydraulic force, they excel in swiftly separating parts, surpassing manual techniques. While an array of off-the-shelf strongback puller design models is accessible, there are instances where bespoke designs become imperative. This …